Steering Systems and Controls

Marine Steering Systems and Engine Controls

The majority of marine steering systems and engine controls available for small craft are one of several types: Mechanical Steering Systems; Hydraulic Steering Systems; Mechanical Engine Controls (throttle & transmission); Electronic Engine Controls (throttle & transmission).

Selecting the an appropriate system is not difficult once the various equipment types, available options and cost considerations are understood.

Mechanical Steering Systems

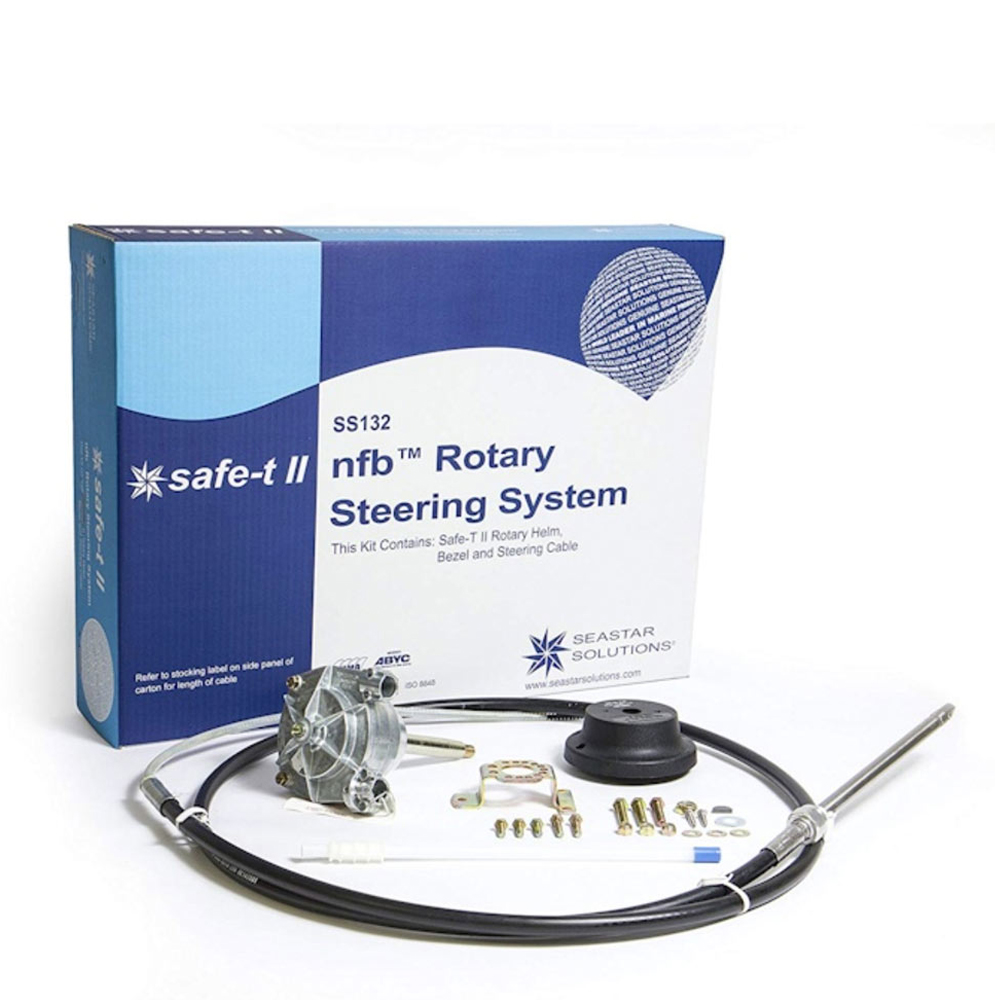

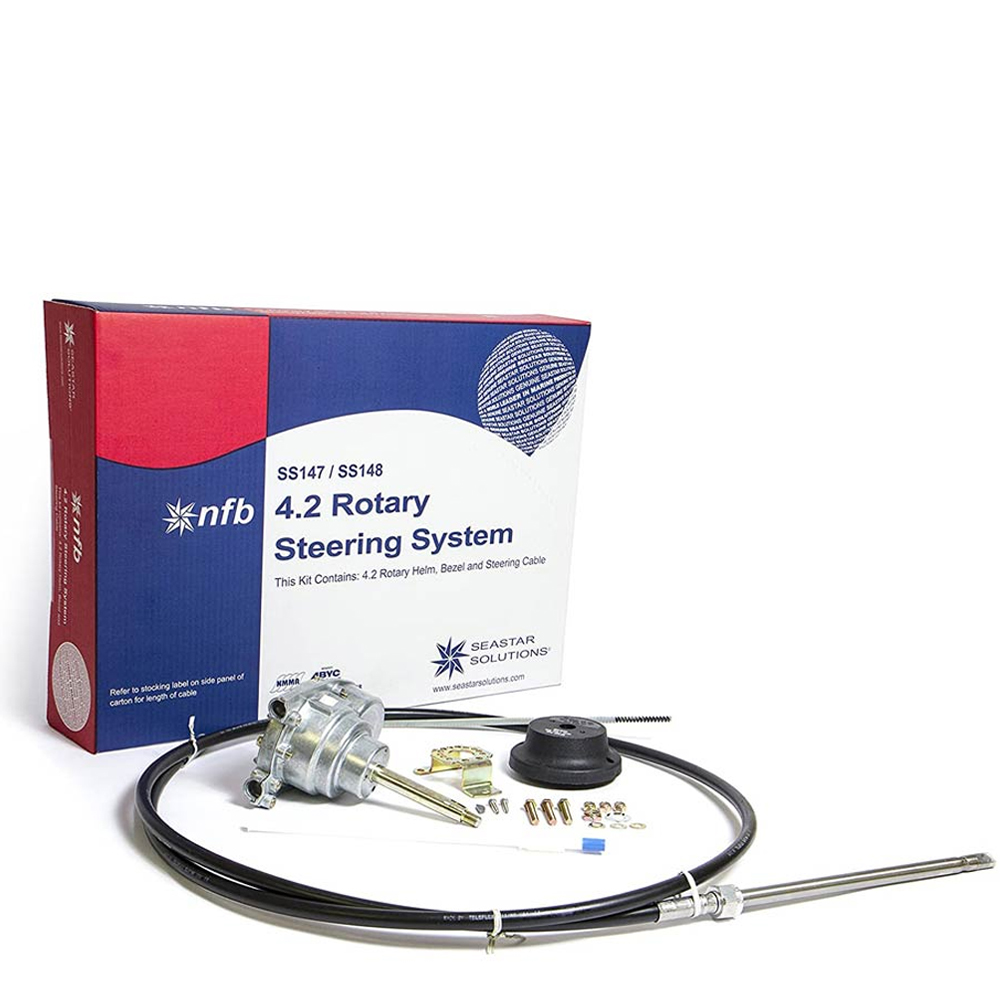

Popular due to it's durability, reliability, and low cost, mechanical cable steering is typically found on boats under 35 feet in length. Mechanical steering systems consist of a steering wheel, mechanical helm, actuator cables with application-specific hardware that connects the cables to the boat's outboard or inboard/outboard engines.

Mechanical systems are available in standard or NFB (no feedback) configurations. No Feedback or Zerotorque steering reduces the rudder torque experienced when driving the boat. The amount of feedback is dependent upon the steering, propeller and the boat. Typically, the faster the boat is traveling, the greater the effort to maintain a straight course.

Marine Mechanical Steering Parts and Components

- HELM: The mechanical helm is a gearbox mounted to the boat's dashboard and is connected to both the steering wheel and the push-pull cables. As the wheel is turned, gears in the helm rotate to actuate the cables that then moves the engine through its steering arc. Helms are available in a rotary gearbox and rack & pinion styles.

- HELM BEZEL: The bezel is a combination trim piece and mounting bracket that covers and supports the mechanical helm gearbox. The bezels are application-specific and must be matched to the helm in use.

- STEERING CABLE: The cable assembly is routed from the helm to the engine or rudder. Cables are sealed in a lubricated, protective covering. Available in a wide variety of lengths to fit many applications. The cable assembly transfers a push-pull motion from the helm to the engine.

- CABLE HARDWARE KIT: Each connection kit is designed to secure the cable to the engine or tiller arm. In some applications the kits may connect multiple engines or rudders.

- STEERING WHEELS: Replacement steering wheels are available in a wide variety of styles, sizes, materials and budgets. Choosing the appropriate wheel will be a matter of personal preference and the boat type (power, sail, etc.).

- TILT STEERING: Tilt steering is a desirable option that adds comfort and the ability to adjust the steering wheel to suit different helmsmen. Typically, a tilt steering upgrade consists of replacing a standard helm with a tilt version and possibly replacing the existing cables.

Servicing Mechanical Steering Systems

Helms and cables are not designed to be dismantled or serviced by the average boater. Repair parts are not available for helms, cables and cable connection kits. Safety considerations require that helms, cables and connection hardware be replaced as units and with compatible/equivalent equipment. Always consult the manufacturer's literature and follow their recommendations.

Hydraulic Steering Systems

Hydraulic steering can be found on a wide variety of boats types and lengths. Hydraulic steering systems consist of a steering wheel, helm pump, hydraulic hoses, hydraulic cylinder with application-specific hardware that connects the cylinder to the boat's stern drive, outboard and inboard engines.

Hydraulic Steering Parts and Components

- HELM: The hydraulic helm is a pump mounted to the boat's dashboard and connected to both the steering wheel and hydraulic hoses. As the wheel is turned, the pump in the helm transfers hydraulic fluid through the hose to the cylinder that then moves the engine through its steering arc.

- HELM BEZEL: The bezel is a combination trim piece and mounting bracket that covers and supports the hydraulic helm pump. The bezels are application-specific and must be matched to the helm in use.

- STEERING HOSE: The hydraulic hose assembly is routed from the helm to the cylinder and then back to the helm pump. Tubing is sometimes used in place of hose in certain inboard and inboard/outboard applications. The hydraulic steering cylinder is attached to the engine and moves the engine through its steering arc. Hydraulic hoses are available in a wide variety of lengths to fit many applications. Modifying hydraulic hose is not recommended and may lead to steering problems, leakage or total failure.

- CYLINDER: Each cylinder with attaching hardware is designed to transfer hydraulic energy to linear motion that moves the engine through its steering arc. In some applications the cylinders may be connected to multiple engines.

- TIE BARS: Each tie bar hardware kit is designed to connect the hydraulic steering system to multiple engines.

- STEERING WHEELS: Replacement steering wheels are available in a wide variety of styles, sizes, materials and budgets. Choosing the appropriate wheel will be a matter of personal preference and the boat type (power, sail, etc.).

- TILT STEERING: Tilt steering is a desirable option that adds comfort and the ability to adjust the steering wheel to suit different helmsmen. Typically, a tilt steering upgrade would consist of replacing a standard helm with a tilt version and possibly replacing the existing hoses. Not all hydraulic steering systems offer a tilting helm as an option.

Servicing Hydraulic Steering Systems

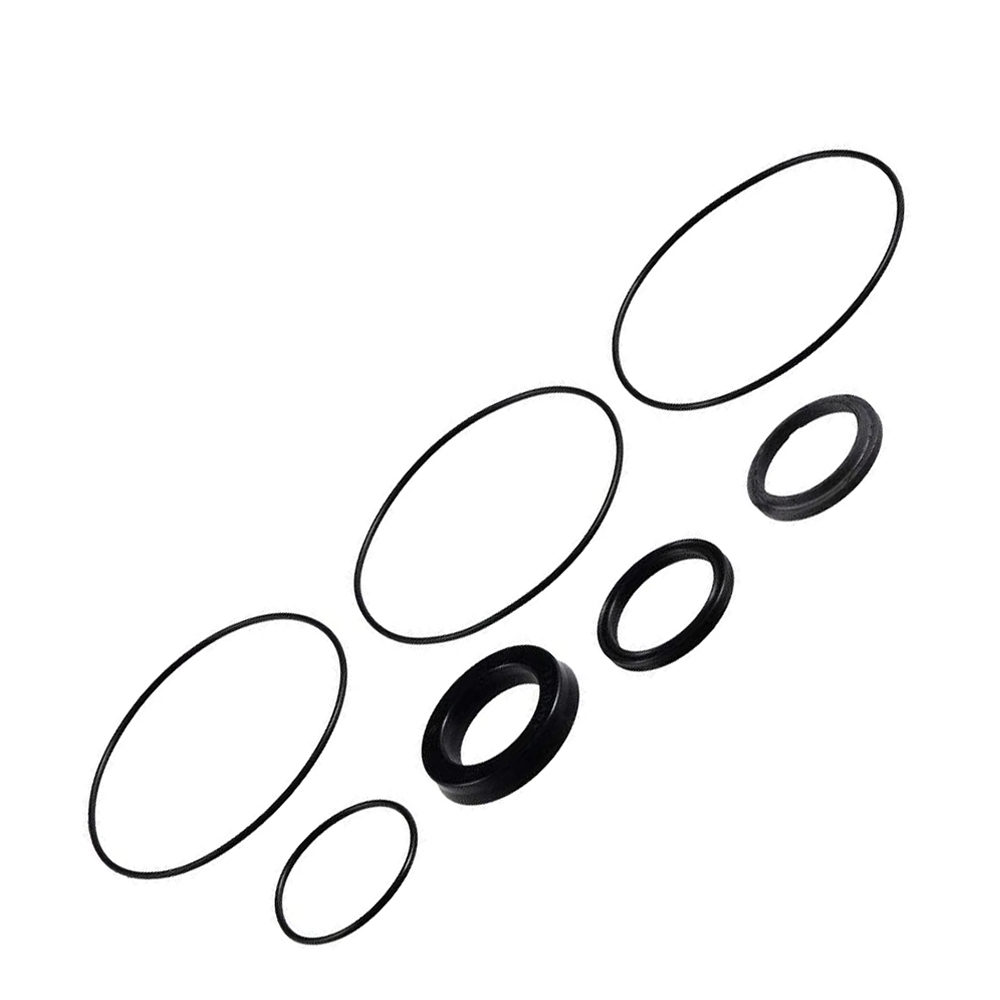

Helm pumps and hydraulic hose assemblies are not designed to be dismantled or serviced by the user. Replacement components are available for many older helm pumps, hydraulic hoses and fitting kits. Safety considerations require that helm pumps, hoses and connection hardware be replaced as units and with compatible/equivalent equipment. Always consult the manufacturer's literature and follow their recommendations.

Engine Control Systems

Engine Control Systems can be found on nearly every watercraft that relies upon an engine for propulsion.

Mechanical Engine Control Systems consist of a lever control, control cables, engine connection kits with application-specific hardware that connects the cables to the engine throttle and transmission.

Mechanical engine controls are reliable, durable and low in cost.

Hydraulic Engine Control Systems provide a simpler method to synchronize multi-station remote station engine throttle and transmission controls. Pliable, light weight nylon tubing is utilized in place of bulky mechanical cables.

Hydraulic components are easy to mount and are reliable in operation.

Electronic Engine Control Systems provide flexibility when it would be difficult or impractical to install multiple mechanical control stations. If the run between stations is complex or long or if there are more than two stations on the boat, electronic engine controls would be the better choice.

Engine Control System Parts and Components

- ENGINE CONTROLS: Dual Function Single-Lever Controls operate both throttle and transmission with a single lever. The dual function control station uses a separate shift cable and throttle cable but both are activated with one lever. Dual Function Single-Lever Controls are available for twin engine applications. While there are two levers on the station, each lever controls the throttle & shift of one engine only.

- Single Function Controls operate only the throttle or transmission with a single lever. The single function control station may feature one lever that would activate the throttle or shift or have two levers that control the throttle and shift separately. Twin engine applications typically feature two two-lever single function station controls.

- Multiple Station Installations typically use single-function two lever controls. There are basically two multiple station system designs. A Parallel Control System has cables from each station that run all the way to the shift & throttle at the engine. The Parallel system is normally used when the cable runs are direct and short. A Series Control System has cables that run from an upper station to a lower station. Additional cables run from the lower station to the throttle & shift at the engine. The Series System is typically used for difficult, longer cable runs. When choosing an engine control configuration always consult the manufacturer's literature and follow their recommendations.

- CONTROL CONNECTION KITS: OEM specific application kits are available, review the manufacturer's literature and follow their recommendations.

- ENGINE CONNECTION KITS: OEM specific application connection kits adapt a wide range of engine manufacturers to a variety of of control cables and stations. It is good practice to r operate only the throttle or transmission

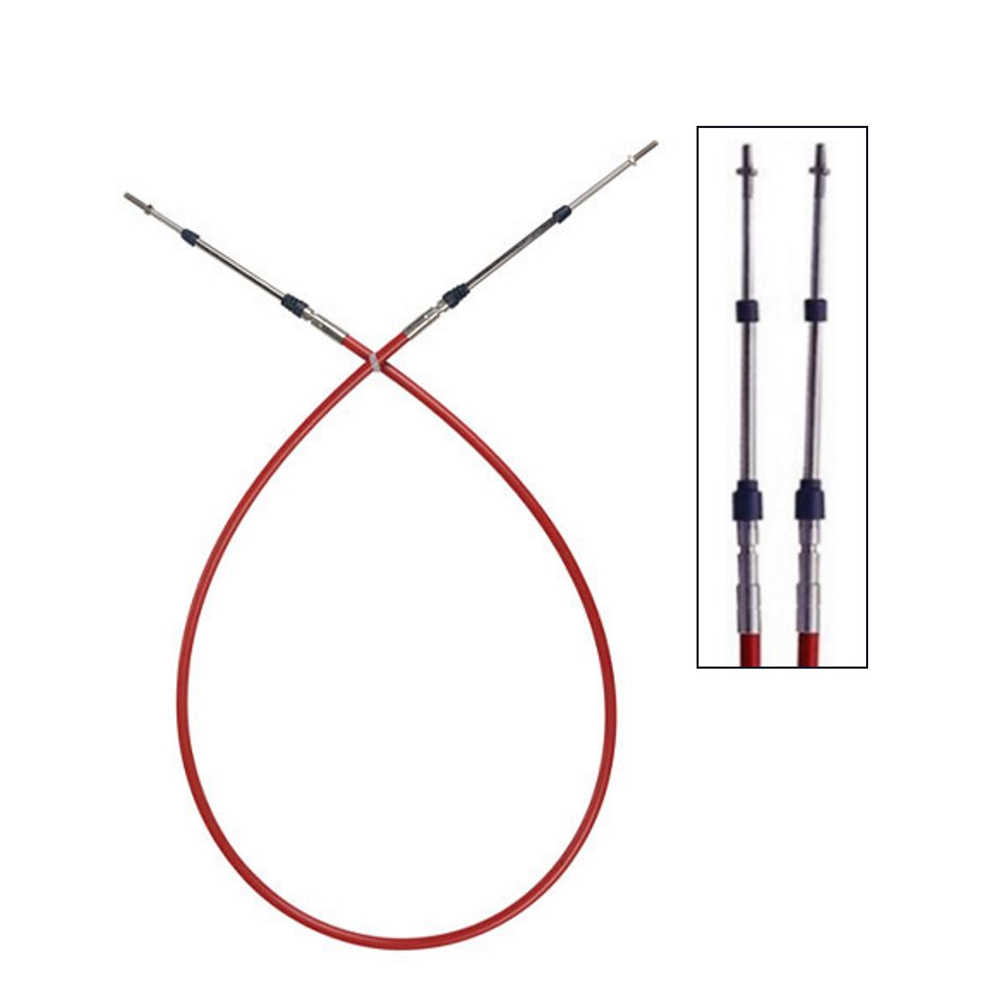

- CONTROL CABLES: Control cables are constructed from corrosion resistant materials and are lubricated for life at the factory. Control cables are available in a wide variety of lengths to fit many applications. Most control cables are available in lengths from six to fifty feet. Control cables are designed to operate the throttle or transmission at the engine. In some applications control cables may connect multiple engines. When routing cables avoid areas of high heat, moving parts, sharp edges, etc. Properly installed cables must not restrict engine movement. Always review the manufacturer's literature and follow their recommendations.

Servicing Engine Control Systems

Controls and cables are not designed to be dismantled or serviced by the user. Repair parts are not available for controls, cables and cable connection kits. Safety considerations require that controls, cables and connection hardware be replaced as units and with compatible/equivalent equipment. Always consult the manufacturer's literature and follow their recommendations.