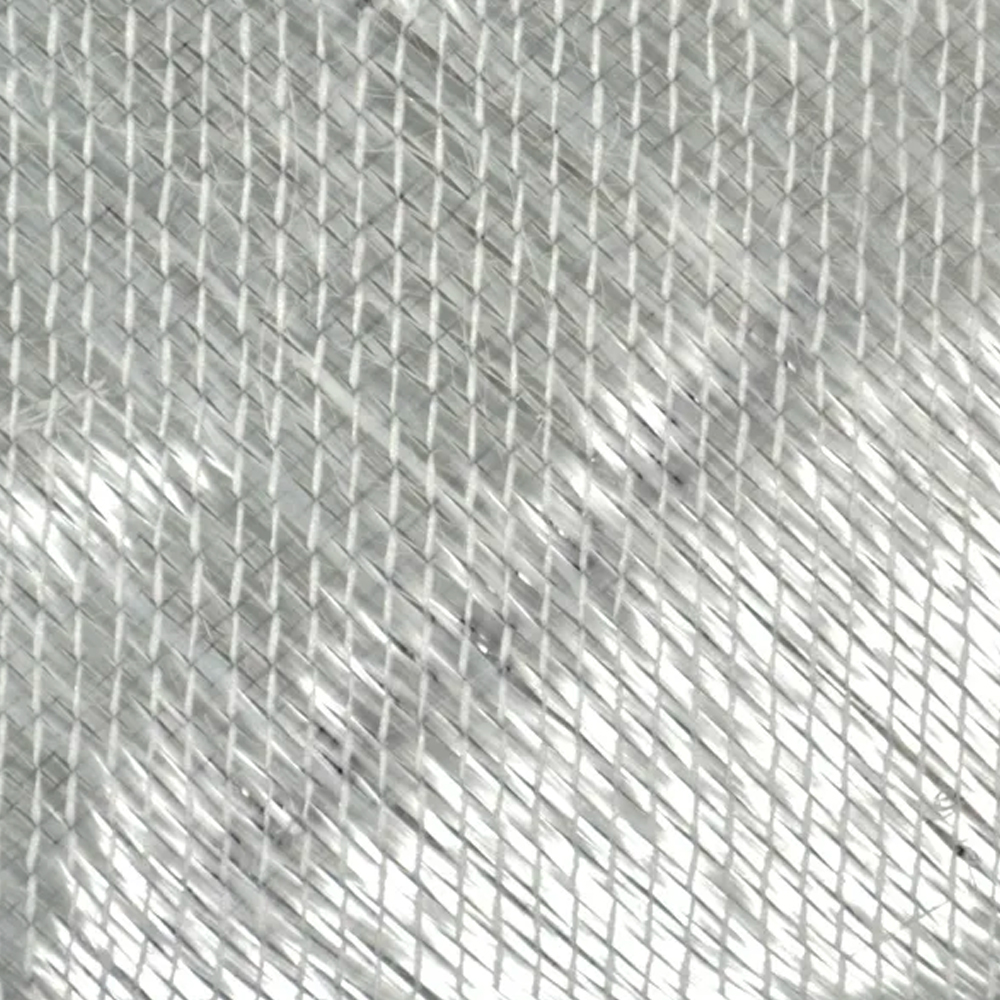

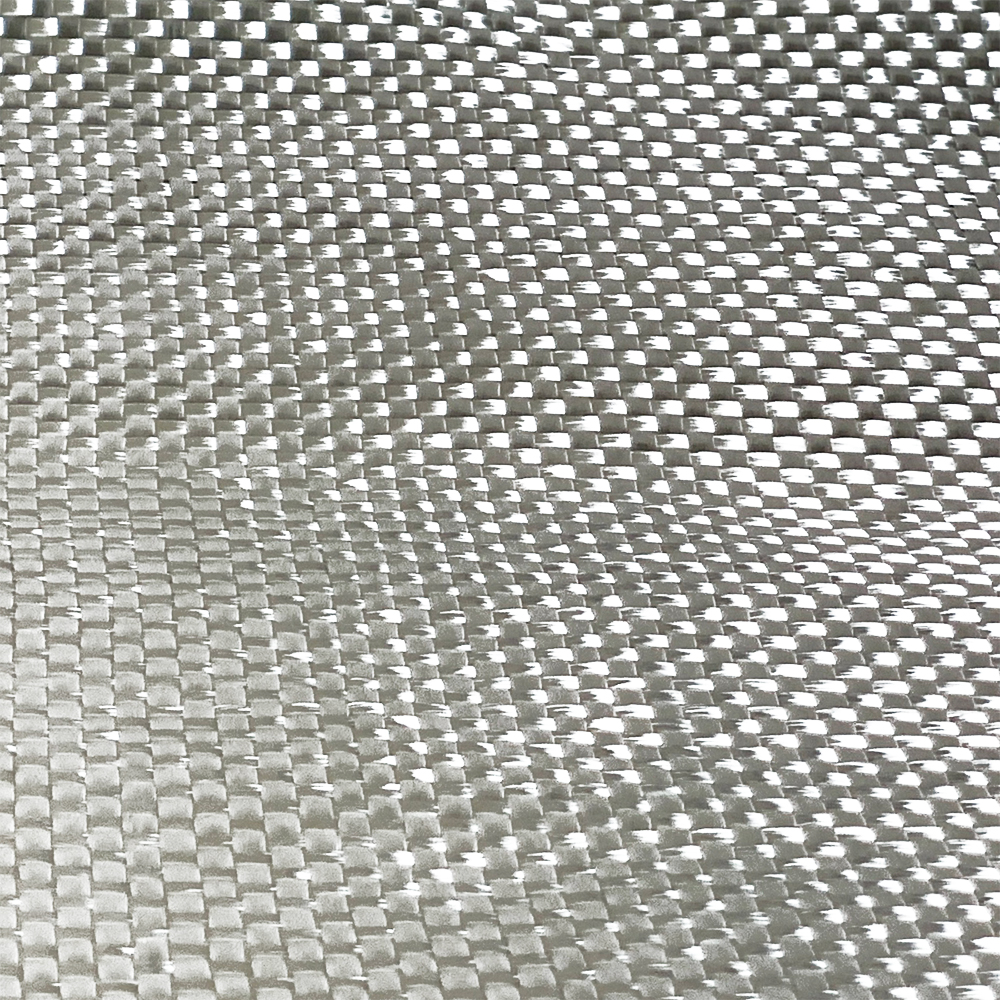

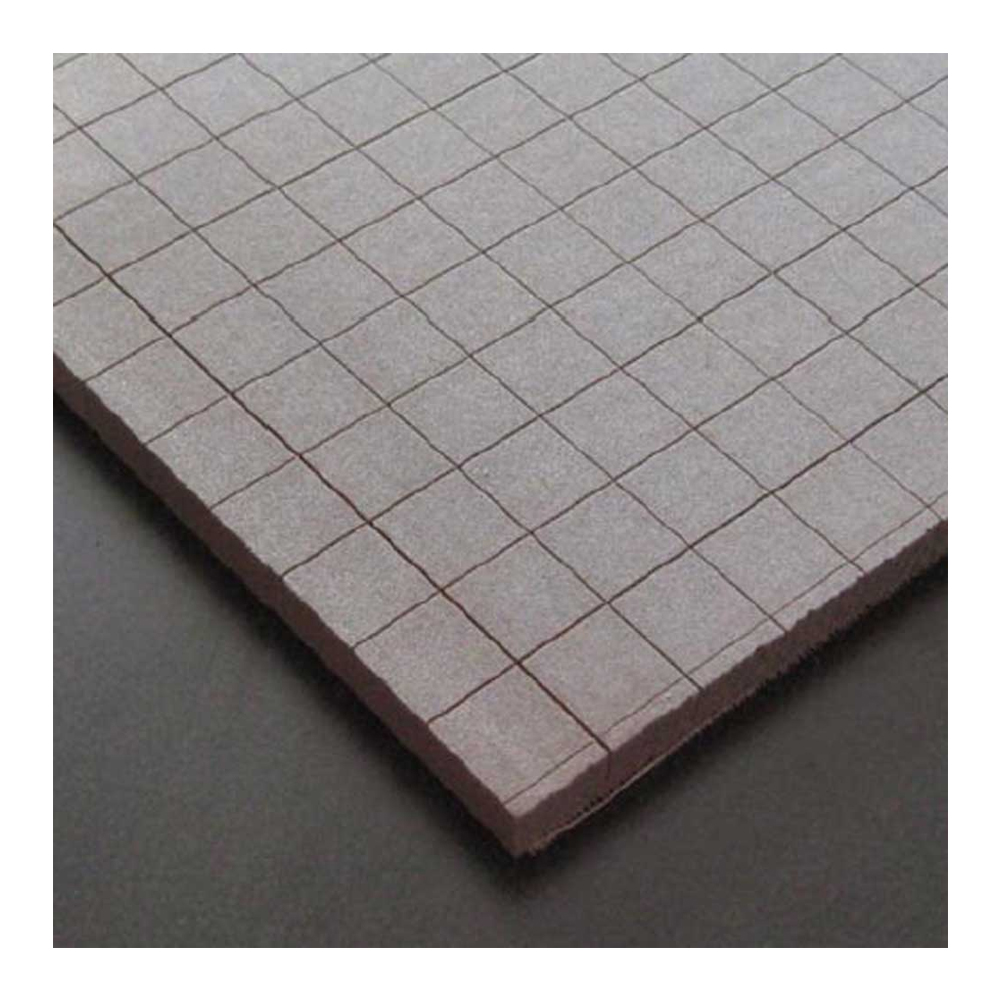

Contoured ProBalsa Plus is a coated, contourable, endgrain Balsa Wood for use in marine and boatbuilding applications. Coated with a thin resin film to enhance bond with epoxy, VE and polyester resin systems. 10 lb. per cubic ft. typical density. Standard core for many OEM boatbuilders. Typical applications include hull and deck core replacement, construction of small parts and inexpensive straight core replacement. Purchase by individual sheets / boards or by the case.

Sold in 2'x4' sheets

DIMENSIONS:

3/8" X 2' X 4'

1/2" X 2' X 4'

3/4" X 2' X 4'

Reviews for Balsa Core - ProBalsa

Verified Purchase

The way they shipped it caused it to crack down the middle, but a little wood glue fixed it perfectly. This balsa is very good quality and since it comes as a single flexible sheet it was perfect for maintaining the shape of the top deck. I used epoxy to glue it to the existing bottom layer, and then poly resin + glass to lay the top. I was pleased with the result. With some new sprayed on gel coat the deck will look new again.

Was this review helpful to you?

Verified Purchase

Used it for coring for a hatch.

Was this review helpful to you?

Verified Purchase

Re-cored the front deck of my 1975 Chris Craft Sport Fish. I had excellent results.

Was this review helpful to you?

Verified Purchase

It came well packed and was just like the picture.

Was this review helpful to you?

Verified Purchase

Easy to use

Was this review helpful to you?

Verified Purchase

My circa '69 14' Pintail had water saturated end-grain balsa deck core. This was exactly what I needed to replace this and rejuvenate this classic sailboat.

Was this review helpful to you?

Verified Purchase

Sandwich between two layers do fiberglass, this wood becomes very ridge.

Was this review helpful to you?

Verified Purchase

Used to re-core a rotten deck on a J/30. Easy to work with, laminated to backing well, arrived rolled up in a reasonable box and on time for my project.

Was this review helpful to you?

Verified Purchase

Pro Balsa is easy to work with.

Was this review helpful to you?

I had a small soft spot in the deck around an inspection plate. I had access to remove the bad core and replace it with the new balsa. After epoxying the balsa in place I remounted the inspection plate.

Was this review helpful to you?