#6 Bronze Wood Screws Flat Head Frearson

#6 Bronze Wood Screws Flat Head Frearson

This item is eligible for free shipping

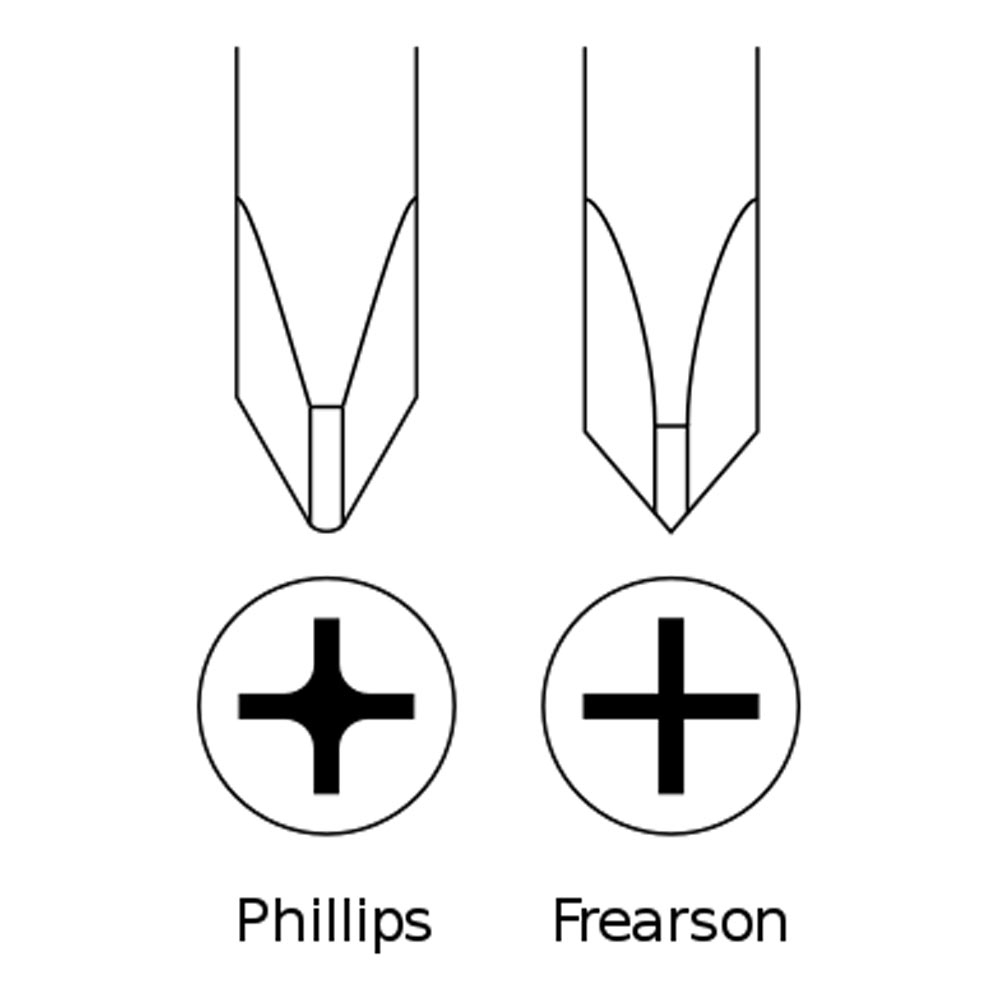

#6 Silicon Bronze Frearson Flat Head wood screws appear similar to the Phillips head but the Frearson has a more pointed 75° V shape. The Frearson tool recess is a perfect cross which minimizes cam out, unlike the Phillips head, which is designed to cam out.

Traditional boatbuilders love these Silicon Bronze wood screws because they have cut threads and the full-bodied diameter shank. Unlike rolled thread screws with their reduced shank--these screws have a shank diameter that is the same size as the outside of the threads. This completely fills the clearance hole normally drilled for the shank thus creating a waterproof seal.

Silicon Bronze is the traditional choice for marine construction. It is corrosion resistant, helps prevent rot around the screw holes when used under water, and is relatively strong. Although stronger than Solid Brass, Silicon Bronze screws are not as strong as Stainless Steel. They require a carefully sized pilot hole to avoid breakage. We recommend drilling twice (once for the root and once for the shank) as well as using fastener lubricant to avoid breakage.

Reviews for #6 Bronze Wood Screws Flat Head Frearson

Verified Purchase

I'm still waiting for a reply on when the second half of my order will ship.

Was this review helpful to you?

Verified Purchase

The only drawback that has me checking other on line for smaller qty of larger screws

Was this review helpful to you?

Verified Purchase

Good for use in a wet environment

Was this review helpful to you?

Best price, excellent delivery service, what more can I add?

Was this review helpful to you?