This item is eligible for free shipping

5200 FC (Fast Cure) is a faster curing version of 3M's popular 5200 marine sealant. With nearly the same tensile strength as original 5200 and significantly faster cure time, Fast Cure is designed for use where permanent bonds are needed quickly.

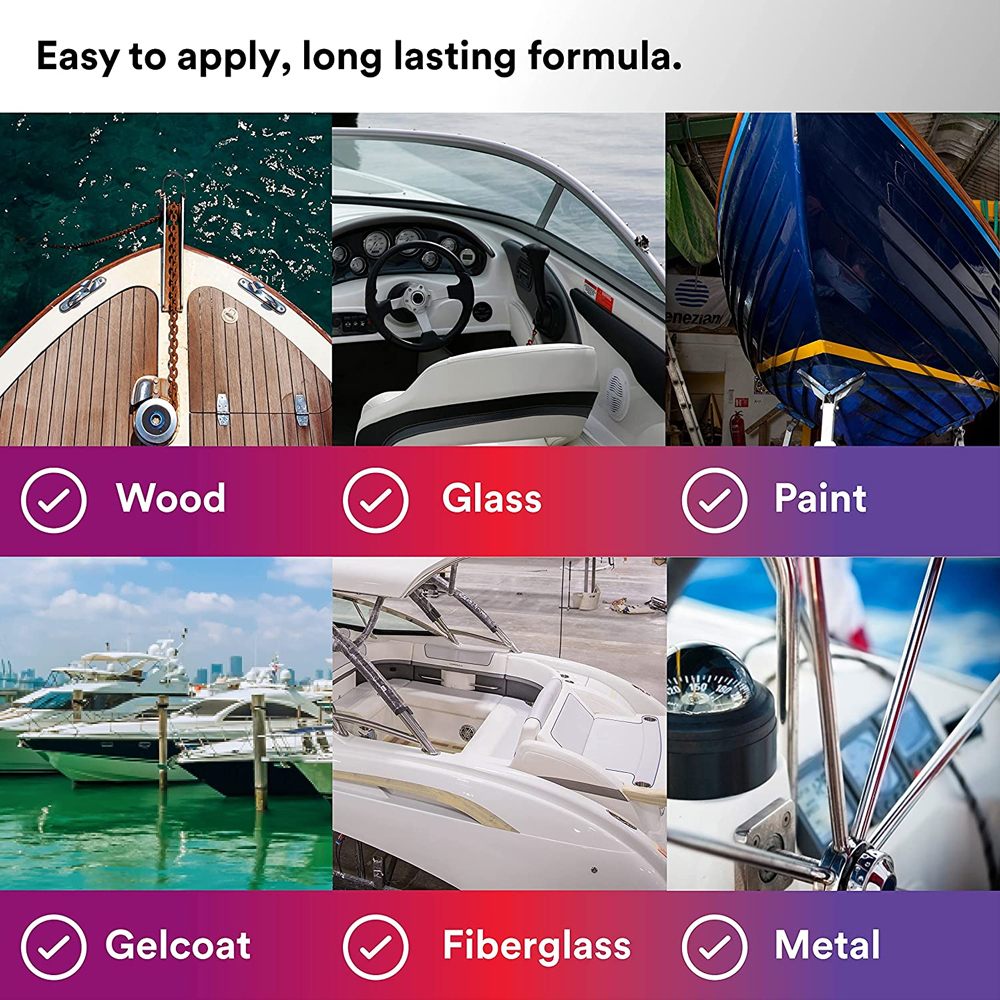

Easy to apply with a standard caulking gun, this high performance polyurethane adhesive becomes tack free in one hour and fully cures in approximately 24 hours. The seal is extremely strong, retaining its strength above or below the water line. 5200 FC stays flexible and allows for structural movement. It has excellent resistance to weathering.

Reviews for 3M 5200 Fast Cure Marine Sealant

Verified Purchase

Doubled up with mechanical fasteners in critical application. Working well to date.

Was this review helpful to you?

Verified Purchase

I got this because I had a really small job to take care of and I like how you can use just a little bit. I still got it all over myself as per normal. I didn't use all of it and put the lid back on. I expect I will be able to use again which is pretty different from the large caulking style tube. Seems like once that is punctured and open, better use it all, first time

Was this review helpful to you?

Verified Purchase

I like 3M 5200 anyway but this little tube is so handy compared to the big cartridge that you use in a caulk gun. My experience with the big tube is that you can't just use a little without wasting the rest of it. This little squeeze tube can replace the lid and get it back open and use a little more again later

Was this review helpful to you?

Verified Purchase

Use on wooden boats

Was this review helpful to you?

Verified Purchase

Iused to seal small hole in block of truck.

Was this review helpful to you?

Verified Purchase

Just used this product to permanently install drain tubes on my center console, excellent.

Was this review helpful to you?

This is a must have if you own a boat.

Was this review helpful to you?

I attempted to fasten heavy rubber liners in a pond that are damp if not wet. This product WILL NOT stick to anything wet or damp.

Was this review helpful to you?

I used this product to repair cracks, seams, and small depressions in a concrete fountain pool before repainting with epoxy paint. It spread beautifully and provided more than adequate tooling time with a standard putty knife. The product did not run or sag on vertical walls. It remained slightly tacky for several days and didn't fully cure for an entire week, but that may have been due to using it on concrete, which wasn't listed as one of its uses. I would recommend tooling as smoothly as possible since the product is not easily sanded, even with a power sander. Overall, I was very pleased with this product. Its bonding strength is phenomenal, yet it remains flexible enough to withstand joint movement.

Was this review helpful to you?