This item is eligible for free shipping

207 Special Clear Hardener was especially developed for use with West System 105 resin in coating applications where an exceptionally clear moisture-resistant natural wood finish is desired.

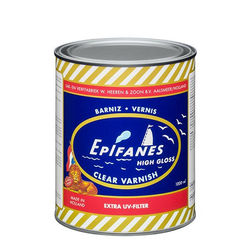

Improved formula chemistry allows for true clear cure with same UV stability without amber tint. An ultraviolet inhibiting additive improves the resistance of a West System 105/207 mixture to sunlight but the cured epoxy surface will still require the additional protection of a quality UV-filtering varnish.

207 is designed to self level for smooth finishes and to wet-out and bond fabrics. Although it provides good physical properties for general bonding applications, it is more difficult to thicken and less cost effective for this purpose than 205 or 206 hardeners. It's also used for laminating veneers where bleed through at joints may be exposed to sunlight.

| Mix Ratio, Resin:Hardener | 3:1 by volume (3.5:1 by weight) |

|---|---|

| Pot life at 72 F (22 C) | 22 to 27 minutes |

| Cure to a solid state | 9 to 12 hours |

| Cure to maximum strength | 4 to 7 days |

| Minimum recommended temperature | 60 F (16 C) |

| Pumps required | 300, 306-23 or 309-3 |

Technical Information

- Excellent long-term clarity due to improved chemistry and stabilization with UV filters

- Superior blush resistance

- Extended recoating time

- Excellent fiberglass wet out characteristics

- Ideal viscosity for buildup coats

- Excellent paint and varnish compatibility

- Excellent physical properties for bonding

Reviews for WEST System 207 Special Clear Hardener

Verified Purchase

Very Clear

Was this review helpful to you?

Verified Purchase

very versatile. Use for coating wood, concrete, etc. Use as an adhesive.

Was this review helpful to you?

Verified Purchase

Expensive but I know can trust the quality.

Was this review helpful to you?

Verified Purchase

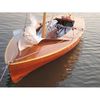

Been using West 207 for many years under a 2-part polyurethane (Epifanes for more than a decade, Interlux Perfection before that) on my south facing deck. Builds quickly and can apply 3 coats in one day, generally all that's needed. Deck looks great after all these years with occasional maintenance (about 5 years in sun, double that in shade). Wood is western red cedar.

Was this review helpful to you?

Verified Purchase

I have been working with epoxy for nearly 40 years and have tried just about all the major manufacturers. I always come back to West because they have the widest line of products. The 207 hardener has proven its superiority in work that is over 25 years old. I'm sticking with West from now on.

Was this review helpful to you?

Verified Purchase

I have been working with epoxy for nearly 40 years and have tried just about all the major manufacturers. I always come back to West because they have the widest line of products. The 207 hardener has proven its superiority in work that is over 25 years old. I'm sticking with West from now on.

Was this review helpful to you?

Verified Purchase

Product worked great ...always does

Was this review helpful to you?

Verified Purchase

Very clear when dry. Easy to work with. Good for the beginner.

Was this review helpful to you?

Verified Purchase

It works great. Use it for everything.

Was this review helpful to you?

Verified Purchase

I have used many other epoxy systems and have issues with amine blush and washing it off. I really like not worrying about it with this product. An excellent hard clear finish.

Was this review helpful to you?