This item is eligible for free shipping

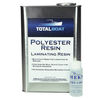

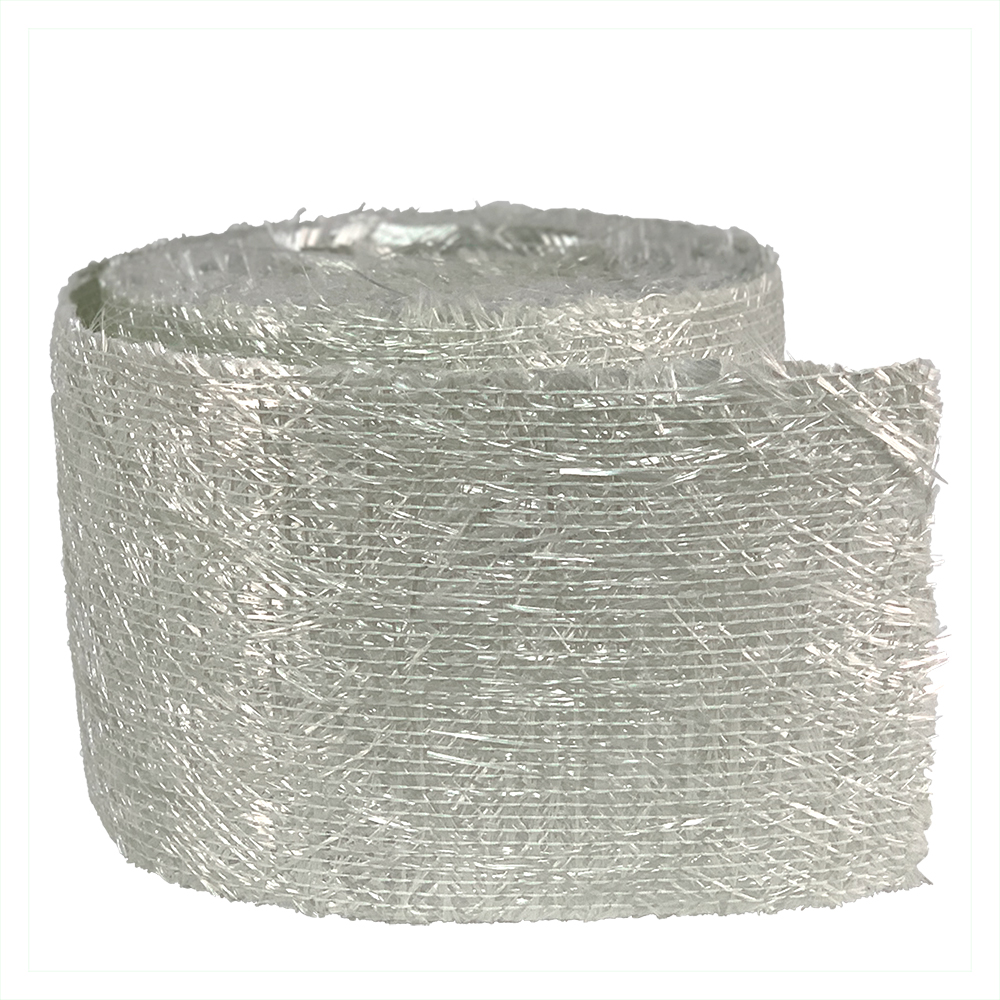

TotalBoat Polyester Laminating Resin is used as a first coat for base coat applications. Without wax, this resin remains tacky to hold fiberglass fabric in place on vertical surfaces. Needs no sanding between coats. Laminating resin is excellent for saturating fiberglass fabrics. MEKP (methyl ethyl ketone peroxide) catalyst included.

Available in Quart and Gallon Kits.

Note: The Polyester Laminating Resin you receive will be either blue or pink in color, depending on the time of year your order is placed. Blue (winter formula) contains more promoter to help it set up more quickly in cooler temperatures; blue will still work in warmer temperatures, but will set up quickly. Pink is the summer formula, intended for use in warmer temperatures.

![]() WARNING: This product can expose you to chemicals including styrene, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals including styrene, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Reviews for TotalBoat Polyester Laminating Resin

Verified Purchase

This is at least my 6th gallon. If I need more I won't hesitate to order more. I lately have ordered from Amazon. I can have it delivered to a Whole Foods to prevent theft.

Was this review helpful to you?

Verified Purchase

I had a large hole in my truck's dashboard. The original dash had hardened & cracked and pieces were missing. Using Total Boat Polyester Resin and fiberglass, I have created a section to strengthen my dash. Final top is a polyester body fill to get it smooth. I am extremely please with the resin and it's working time. Shaving the fiberglass after hardening was not difficult and the end result will be nice.

Was this review helpful to you?

Verified Purchase

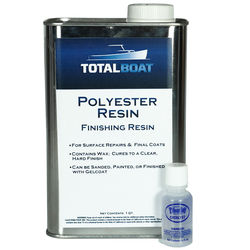

No need to sand between layers anymore! Mixing is straight forward, add a set number of ounces into the mixing cup and then 7 drops of the other stuff per ounce. I like to do 12 ounces at a time and have gotten really quick at counting to 84! It is important to mix for a full minute (time yourself so you don't cut it short) so that it is fully mixed and will then set well. This gives plenty of working time in temperatures up to the low nineties (haven't worked with it hotter than that). The resin soaks into the fiberglass easily and the wetted surface bonds very strongly to the layer before it to easily build your surface up. It is important to also have a can of Finishing Resin (contained wax) to put over your project as a top coat so that the piece will cure at the end. I normally just paint the Finishing Resin over the piece at the end for a nice smooth shine after sanding and fairing is completed.

Was this review helpful to you?

Verified Purchase

Great consistent quality.

Was this review helpful to you?

Verified Purchase

Thanks for making such a great system. I've never done any glass work and you guys made it easy. I molded my own "hood scoop" and grafted it onto my propane hatch. Now I can run (2) vertical tanks and double my time between refills…

Was this review helpful to you?

Verified Purchase

The Total Boat polyester resin is excellent stuff! I've used 10's of gallons of this Total Boat polyester resin for various projects, most notably for making female moulds for automotive body kits. Unlike the 3M Bondo polyester resin (commonly available at big box hardware stores), the Total Boat polyester resin is thin like water and mixes very easily with the mekp. You need a low viscosity resin (like Total Boats) for it to be sucked up by CSM Fiberglass and break down the styrene binder, otherwise if the resin is too viscus (like the 3M Bondo resin) it will not properly break down the styrene binder in CSM. One tip i have learned, is not too add too much mekp. When the resin 'kicks' if it gets too hot too quickly it can warp. Mixing too little mekp is fine, but it could take a little over a day to cure.

Was this review helpful to you?

Verified Purchase

If you're buying laminating resin, get more than you need. I struggled to find this locally so I should have gotten more.

Was this review helpful to you?

Verified Purchase

Terrific for large layups. Sets up in a couple hours and can put multiple layers on in a day. Needs to be coated with finishing resin, wax, or PVA to cure or it will clog sanding pads pretty quick

Was this review helpful to you?

Verified Purchase

Been through quite a few gallons of this by now, and never had an issue. Performance is great, reliable curing.

Was this review helpful to you?

Verified Purchase

Use it for repairing my boat. Works great. A little off topic. First gallon I ordered, it looks green. Second gallon, it looks a little purplish. not sure if it matter with anyone. I have no problem.

Was this review helpful to you?