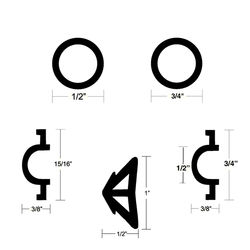

Brass Solid Back Half Oval Trim features solid brass construction. Not pre-drilled.

Sold in 6' and 12' lengths only. 3/8" and 1/2" brass half oval can be rolled and packaged for UPS shipment. 12 ft continuous lengths of 5/8" and larger widths must be shipped motor freight.

| Item Number | Width x Length |

|---|---|

| ROD-BR23796 | 3/8 in. x 6 ft. |

| BHO-SB12-6 | 1/2 in. x 6 ft. |

| BHO-SB12-12 | 1/2 in. x 12 ft. |

| BHO-SB58-6 | 5/8 in. x 6 ft. |

| BHO-SB58-21 | 5/8 in. x 12 ft. |

| BHO-SB34-6 | 3/4 in. x 6 ft. |

| BHO-SB34-12 | 3/4 in. x 12 ft. |

| BHO-SB1-6 | 1 in. x 6 ft. |

| BHO-SB1-12 | 1 in. x 12 ft. |

| BHO-SB114-6 | 1-1/4 in. x 6 ft. |

| BHO-SB114-12 | 1-1/4 in. x 12 ft. |

| BHO-SB112-6 | 1-1/2 in. x 6 ft. |

Reviews for Solid Back Brass Half Oval Trim

Verified Purchase

One of my 5 pieces had a scratch that is not easily rubbed out. I have drilled & countersunk over 100 holes. I had to get the correct size screws from a local hardware store because you don't have them. My experience with you and this rub rail could have been better.

Was this review helpful to you?

Verified Purchase

Used it for a rub rail on a dinghy. Tricky to drill and counter sink for screws. Wish it was pre drilled.

Was this review helpful to you?

Verified Purchase

This brass half round is ideal for stem piece on my canoes. It's easy to use and reinforces this area tremendously. Came shipped in a coil that required straightening this time unlike the last when it came flat and strait in a tube...is a great product that is hard to find anywhere else.

Was this review helpful to you?

Verified Purchase

I'm restoring a 1962 Dyer Dhow 7'11" dinghy, and replaced the skeg with a nice piece of white oak. I wanted to protect it further from being dragged up on a beach. This was the perfect size. I only needed about 18" of it but have plenty left for other projects.

Was this review helpful to you?

Verified Purchase

Was thrilled how quickly I got my order. Brass was easy to cut, drill, and polish. Used it as chafe guard on teak toe rail of my Cape Dory 30. Highly recommend the product.

Was this review helpful to you?

Verified Purchase

I spent considerable time trying to straighten a badly bent product. The box it was shipped in folded during shipment and put some nasty kinks in the half oval.

Was this review helpful to you?

Verified Purchase

Matches my boat trim exactly.

Was this review helpful to you?

Ordered a length of 3/8 for use on canoe stems. Went with rolled shipping to save money. Material is pretty stiff & springy, so it mostly straightened out on unpacking. It will take a little work to bend it to the right curve using some kind of rounded form, but it should work OK. Unless I needed a piece that was dead flat and straight, I wouldn't hesitate to use the rolled shipping method again. It will need a little polishing to to get rid of the tarnish and get a bright shine, but overall looks good.

Was this review helpful to you?

Verified Purchase

I purchased this brass for a cedar strip canoe I was rehabbing. Originally I orederd a 12 foot piece. A day later I got an email that it was backordered, and I asked if I could swithch it to two 6 foot pieces, which they did immediately. A couple of days later, it was delivered, in time for me to put it on the canoe and go paddling. Excellent customer service and delivery.

Was this review helpful to you?

Verified Purchase

easy to soldier

Was this review helpful to you?