This item is eligible for free shipping

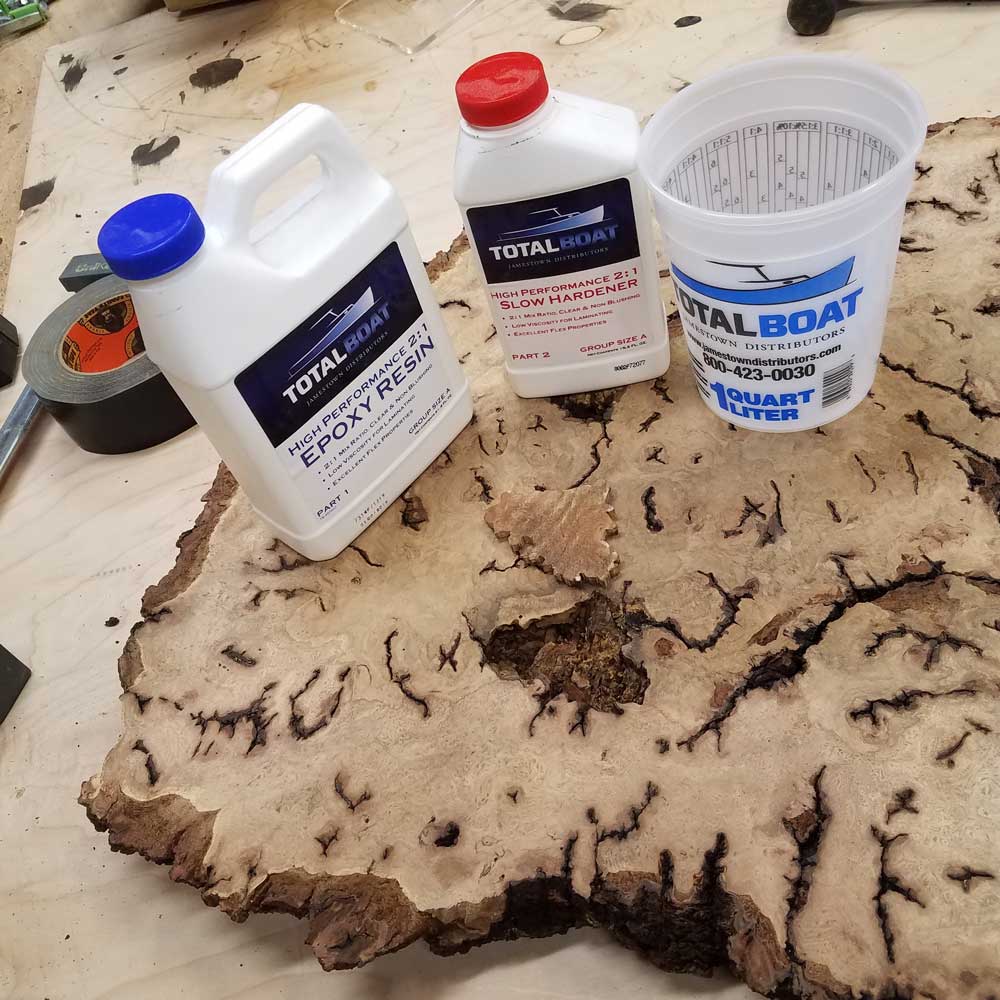

TotalBoat High Performance Epoxy Kits are great for clear coating, laminating, sealing, glassing, vacuum bagging & epoxy repair projects where a crystal-clear cure is essential. This unique epoxy system also has flex properties ideal for wooden boats.

Project-ready kits include TotalBoat High Performance Epoxy Resin, non-blushing High Performance Hardener in your choice of hardener speed (slow, medium, or fast), and calibrated epoxy pumps for the exact ratio of resin to hardener.

Group Sizes: A, Quart Kit; B, Gallon Kit; C, 2 Gallon Kit. Choose group size and select Slow, Medium, or Fast Kit. Pint Kit (Size M, slow hardener only) is perfect for sampling or really small projects.

| Item Number | Group Size | Kit Size / Speed | Kit Contents |

|---|---|---|---|

| TB-0221KITSM-K | M | Pint Kit / Slow | Group Size M High Performance Resin (1 Pint) & High Performance Slow Hardener (1/2 pint), 2 Mixing Pots (does not include pumps) |

| TB-0221KITSA-K | A | Quart Kit / Slow | Group Size A High Performance Resin (1 Quart) & High Performance Slow Hardener(1 pint), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITMA-K | A | Quart Kit / Medium | Group Size A High Performance Resin (1 Quart) & High Performance Medium Hardener(1 pint), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITFA-K | A | Quart Kit / Fast | Group Size A High Performance Resin (1 Quart) & High Performance Fast Hardener(1 pint), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITSB-K | B | Gallon Kit / Slow | Group Size B High Performance Resin (1 Gallon) & High Performance Slow Hardener (1/2 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITMB-K | B | Gallon Kit / Medium | Group Size B High Performance Resin (1 Gallon) & High Performance Medium Hardener (1/2 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITFB-K | B | Gallon Kit / Fast | Group Size B High Performance Resin (1 Gallon) & High Performance Fast Hardener (1/2 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITSC-K | C | 2 Gallon Kit / Slow | Group Size B High Performance Resin (2 Gallons) & High Performance Slow Hardener (1 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITMC-K | C | 2 Gallon Kit / Medium | Group Size B High Performance Resin (2 Gallons) & High Performance Medium Hardener (1 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| TB-0221KITFC-K | C | 2 Gallon Kit / Fast | Group Size B High Performance Resin (2 Gallons) & High Performance Fast Hardener (1 Gallon), Metered Pumps, Instruction Sheet, 2 Mixing Pots |

| Properties (Admixed) | High Performance Fast Hardener | High Performance Medium Hardener | High Performance Slow Hardener |

|---|---|---|---|

| Color | Clear | Clear | Clear |

| Mix Ratio by Volume (Resin:Hardener) | 2:1 | 2:1 | 2:1 |

| Mix Ratio by Weight (Resin:Hardener) | 100A:46B | 100A:45B | 100A:45B |

| Initial Mixed Viscosity at 77°F | 650 cP | 600 cP | 600 cP |

| Gel Time at 77°F (150g mass) | 10 minutes | 25 minutes | 40 minutes |

| Tack-Free Time at 77°F | 2 hours | 3 hours | 5 hours |

| Full Cure at 77°F | 2 days | 3.5 days | 5 days |

| Minimum Recommended Temperature | 55°F | 55°F | 55°F |

| Tensile Strength | 7,700 psi | 8,000 psi | 7,300 psi |

| Tensile Modulus | 380,000 psi | 390,000 psi | 360,000 psi |

| Tensile Elongation | 7.5% | 7.0% | 6.7% |

| Flexural Strength | 11,600 psi | 11,600 psi | 10,200 psi |

| Flexural Modulus | 330,000 psi | 360,000 psi | 330,000 psi |

| Compressive Strength | 9,500 psi | 9,900 psi | 8,900 psi |

| Hardness, Shore D | 84 | 83 | 83 |

| Intended for Clear Coating Applications? | Yes | Yes | Yes |

| Maximum Pour Depth, Per Layer | ||

|---|---|---|

| High Performance Fast Hardener | High Performance Medium Hardener | High Performance Slow Hardener |

| Less than 1/8'' | 1/8'' | 1/4'', up to 75°F, for larger pours, slabs |

| 1/8'', over 75°F, for larger pours, slabs | ||

| 3/8'', up to 75°F, for smaller castings using up to 1 oz. of epoxy | ||

| 1/4'', over 75°F, for smaller castings using less than 4 oz. of epoxy |

Compare to MAS Low-Viscosity Epoxy and System Three Epoxy. You'll find our High Performance epoxy system combines the best characteristics of each: its low-viscosity is incredibly user-friendly for wetting out fiberglass cloth in layups, it cures clear to showcase the natural beauty of wood and has greater flexibility than 5:1 systems, which makes it a perfect fit for wooden boat, canoe, or kayak builds.

High Performance Epoxy Resin and Hardeners can be measured in one of three ways:

- By weight

- By volume

- Using the TotalBoat 2:1 Epoxy Pumps

High Performance Epoxy Resin System Benefits

Low Viscosity Resin: This low-viscosity epoxy resin saturates fiberglass fibers quickly, easily, and completely to reduce the amount of material, time, and labor needed for layups, laminating, and vacuum bagging.

Three Hardener Speeds to Control Cure Time: Fast, Medium, and Slow High Performance Hardeners allow you to control the pot life and cure times to suit your particular working conditions. For example, the High Performance Fast Hardener cures the fastest at room temperature, and can even cure overnight in low temperatures (minimum 55°F). Even better, you can craft your ideal working properties and pot life by combining the different hardeners with each other, but always remember to maintain the proper ratio of 2 parts resin to 1 part hardener by volume.

More Flexible Cure: The High Performance Epoxy System cures to a more flexible finish than traditional resins, too, making it a better choice for wooden boats and kayaks that typically flex during use, as well as expand and contract with changes in temperature and humidity.

Blush-Free: This non-blushing system eliminates the time consuming washdowns between coats typically needed when using traditional 5:1 resin systems.

Low Odor, Low VOC, and BPA-Free—Better for You and the Environment: Low-VOC, low-odor formula is better for use indoors or outdoors. The low VOC content is especially good for use in areas with environmental restrictions. The cured epoxy surface is also BPA-free, making it safer for potential contact with food.

How to Use TotalBoat High Performance Epoxy Resin

TotalBoat High Performance Epoxy Resin can be combined with any of our TotalBoat High Performance Hardeners (Fast, Medium, and Slow) for exceptional results.

TotalBoat epoxy resin and hardeners are packaged and labeled according to group sizes (A, B, C) to ensure you have enough material for your project at the best value.

Clear-coating applications:High Performance Resin and Hardeners are clear in color and are ideally suited for clear-coating applications.

Resin and Hardeners can be measured either by pouring or by using the calibrated TotalBoat 2:1 Epoxy Pumps.

Personal Safety: For your safety, please be sure to wear protective gloves and eye, face, and clothing protection when working with epoxy resin and hardeners. Also, be sure your work area has adequate ventilation.

USING THE TOTALBOAT 2:1 PUMPS FOR DISPENSING TOTALBOAT HIGH PERFORMANCE EPOXY RESIN AND HARDENERS

The procedure for dispensing TotalBoat High Performance Epoxy Resin and any of the High Performance Hardeners properly is ALWAYS ONE full pump of resin to ONE full pump of hardener. TotalBoat pump sets are calibrated to dispense the accurate mix ratio automatically.IMPORTANT! Proper mix ratios are critical when working with epoxy resin and hardeners in order to achieve a proper cure.

★ TotalBoat High Performance Epoxy Resin used with TotalBoat High Performance Fast Hardener, TotalBoat High Performance Medium Hardener, or TotalBoat High Performance Slow Hardener is mixed at a ratio of 2 parts resin to 1 part hardener by volume.

TotalBoat 2:1 Epoxy Pumps are calibrated to dispense the proper mix ratio of TotalBoat High Performance Epoxy Resin and TotalBoat High Performance Hardener automatically.

- Use the TotalBoat 2:1 Epoxy Pump Set when using TotalBoat High Performance Epoxy Resin with:

- TotalBoat High Performance Fast Hardener

- TotalBoat High Performance Medium Hardener

- TotalBoat High Performance Slow Hardener

Remember, the procedure for dispensing TotalBoat High Performance Resin and High Performance Hardener properly is always ONE full pump of resin to ONE full pump of hardener.

When using the pump dispensing method for measuring TotalBoat High Performance Epoxy Resin and TotalBoat High Performance Fast Hardener, TotalBoat High Performance Medium Hardener, or TotalBoat High Performance Slow Hardener, use ONLY the TotalBoat 2:1 Epoxy Pumps. These pumps are calibrated to dispense the accurate 2:1 mix ratio automatically. DO NOT use pumps from any other manufacturer; DO NOT use the TotalBoat 5:1 or 3:1 Epoxy Pumps.

NOTE: Adding more hardener does not make the epoxy set faster. It throws off the mix ratio and will not cure properly.

PRIME THE RESIN AND HARDENER PUMPS BEFORE DISPENSING

Push down and release the head of each pump several times until you get a steady stream of liquid without any air pockets.COLD WEATHER OPERATION: Cold temperatures make the viscosity of resin and hardeners increase and may require more force to pump thicker materials. Excessive force on either one of the plunger heads however, may also cause the pumps to break. Dispensing material in 60-70°F is recommended for optimal pump performance.

In cooler temperatures, warming the containers prior to pumping will decrease the epoxy viscosity, making materials pump more easily.

MIXING

After dispensing resin and hardener into a plastic mixing pot, use a wooden stir stick to mix thoroughly.PERSONAL SAFETY: For your safety, please be sure to wear protective gloves and eye, face, and clothing protection when working with epoxy resin and hardeners. Also, be sure your work area has adequate ventilation, and that you wear a proper respirator.

Reviews for TotalBoat High Performance Epoxy Kits

Verified Purchase

Use for filling cracks and small holes Saves a lot of time waiting

Was this review helpful to you?

Verified Purchase

Used this with mat to repair broken hood on an agricultural machine. Worked very well.

Was this review helpful to you?

Verified Purchase

I have been using total boat high performance epoxy for several years now. It works great for laminating, waterproofing, & gluing my wood rc racing boats together that do not have an easy life and it has never let me down. It always sets up like it should when you use the included 2 to 1 pumps or a set of scales. Thanks Total Boat !!

Was this review helpful to you?

Verified Purchase

I layer this into a soap dish sized mold, it's been working for several years now. I like that you can choose the hardening speed. Also, amazingly, the price is right, compared to other resins on the market.

Was this review helpful to you?

Verified Purchase

I used this on some cabinet doors for an outside BBQ storage cabinet. It went on great and covered well.

Was this review helpful to you?

Verified Purchase

This epoxy worked well for my boat build. I chose epoxy over polyester resin and I'm glad I did. Epoxy has low odor, and easy clean up with acetone. The medium set was ideal for my application on a 1/24" scale shrimp boat.

Was this review helpful to you?

Verified Purchase

Hi, I am sure this would have worked but I uncovered a larger issue and was unable to use it. If you know someone in the Galveston TX area that would like to purchase it from me, please reach out to me. I ended up having to replace the entire floor.

Was this review helpful to you?

Verified Purchase

This was only my second epoxy project and I would only choose Total Boat. Why? Because when I first started I called their support line and discussed my project with them and they told me which epoxy to buy, how much I needed and how to best pour it. You cannot find better customer support than this.

Was this review helpful to you?

Verified Purchase

I make a lot of small epoxy items and several times my designs failed but total boat table top never fails in my experience !

Was this review helpful to you?

Verified Purchase

Solo building a foam core 16 ft. skiff. Extended work time, clear, no blush, and remarkably low solvent odor compared to others I tested prior to building.

Was this review helpful to you?