This item is eligible for free shipping

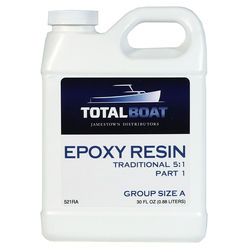

TotalBoat 5:1 Epoxy Kits include everything you need to tackle marine epoxy repairs and fiberglass projects. The five part resin to one part hardener ratio is considered the traditional marine epoxy system of choice for projects like bonding, coating, fairing, filleting, and laminating.

Complete project-ready epoxy kits includes: TotalBoat 5:1 epoxy resin; your choice of either fast or slow TotalBoat hardener; and calibrated epoxy pumps that dispense the right ratio of resin and hardener.

System Group Sizes: A - Quart Kit; B - Gallon Kit; C - 4.5 Gallon Kit.

Note: Don't need the pumps? Gallon size kits are also available with just resin & hardener included. This 'no frills' version makes sense if you just need more epoxy.

| HANDLING PROPERTIES | Fast Kit | Slow Kit |

|---|---|---|

| Mix Ratio by Weight | 100A (Resin) : 18B (Hardener) | 100A (Resin) : 17B (Hardener) |

| Mix Ratio by Volume | 5A (Resin) : 1B (Hardener) | 5A (Resin) : 1B (Hardener) |

| Initial Mixed Viscosity at 75°F, cP | 1,000 | 700 |

| Pot Life at 75°F, 150g mass, min. | 12 | 20 |

| Work Life at 75°F, Thin Film, min. | 60 | 90 |

| Cure Time at 75°F, Thin Film, hrs. | 6 | 10 |

| PHYSICAL PROPERTIES | ||

| Tensile Strength, psi | 8,000 | 7,500 |

| Tensile Modulus, psi | 410,000 | 460,000 |

| Tensile Elongation, % | 3.5 | 4.5 |

| Heat Deflection Temperature | 120 | 125 |

| Compressive Strength, psi | 11,500 | 11,500 |

| Flexural Strength, psi | 14,400 | 12,000 |

| Flexural Modulus, psi | 460,000 | 450,000 |

| Cured Density, g/cm 3 | 1.18 | 1.18 |

| Volumetric Yield in 3 /lb. | 23.5 | 23.5 |

| Volumetric Shrinkage, % | 4.4 | 4.4 |

| Hardness, Shore D | 84 | 83 |

| Color | Amber | Amber |

| Should I use this for clear-coating applications? | No | No |

For clear-coating applications, or where an ultra clear cure is important, we recommend TotalBoat High Performance 2:1 Epoxy.

For extra long pot life and working time, use TotalBoat Tropical Epoxy.

Tip: Wash cured epoxy with water, scrubbing lightly with a Scotch-Brite pad to remove any amine blush prior to over=coating or painting.

Important Safety Information

Always wear protective clothing and equipment to protect your eyes, skin, and lungs when working with TotalBoat Traditional Epoxy Resin and Hardeners. Personal protective clothing should include appropriate gloves, safety glasses or goggles, a proper respirator, and a proper apron or similar protective clothing.

![]() WARNING: The TotalBoat 5:1 Epoxy Slow Hardener can expose you to chemicals including bisphenol A, which is known to the State of California to cause female reproductive toxicity. For more information, go to www.P65Warnings.ca.gov

WARNING: The TotalBoat 5:1 Epoxy Slow Hardener can expose you to chemicals including bisphenol A, which is known to the State of California to cause female reproductive toxicity. For more information, go to www.P65Warnings.ca.gov

Reviews for TotalBoat Traditional 5:1 Epoxy Kits

Verified Purchase

Wood came out great.

Was this review helpful to you?

Verified Purchase

Switched over to this epoxy from Using West system for years. The pumps are a great addition so that people can get the correct mix. I have recently started using a scale to measure my mixes because the pumps do get messy and take up space. Using the scale with the 5:1 ratio is spot on. I will be using this epxy going forward with all of my repair projects.

Was this review helpful to you?

Verified Purchase

So far so good, this is the third time I have ordered this kit and my only complaint would be that the hardener always runs out long before the epoxy does. And it is not by a little amount - forcing the purchase of a new kit and then making the next amount match even less. It would be nice if the dispensed quantities matched a bit better. Other than that, I love Totalboat products and they have always been very helpful.

Was this review helpful to you?

Verified Purchase

This is the third time I've ordered this combo from Total Boat. I don't use it on a boat, I use it for custom fiberglass work on Custom Motorcycles. It is so easy to use, easy to mix and easy to lay out. I will never use another product.

Was this review helpful to you?

Verified Purchase

I'm a DIY boat owner out of necessity, I couldn't afford my boat if I didn't do all repairs and upgrades myself. But I also really enjoy working on boats and have found Totalboat products to be my default "go-to" materials of choice. The quality is excellent, pricing is quite fair and their support is just great. I've used gallons of this epoxy over many years (and several boats) and have never been disappointed, I hope to keep using it for years to come!!!!!!!!!!!

Was this review helpful to you?

Verified Purchase

I purchased this product to fill in some holes in my transom. I could have used 3M 5200 as a cheap seal, but epoxy is harder and more resilient. It also works well when using a syringe to inject into the holes. The 5:1 pump mixing technique works great! It makes mixing easy and is less messy.

Was this review helpful to you?

Verified Purchase

I purchased this to adhere two 8" wide cypress boards together on their faces to make two boat oars. I had never used this product before and didn't know how much to mix or how it would go. My boards were 8 feet long. So I pumped enough to fill their mixing containers half full. This was based on the coverage they stated for a gallon. I stirred it and then applied it with a foam brush. When I was finished with one board, I had only used about 1/4 of the mixed resin. So I applied it to the other board too. Then I put the 2 boards together and started clamping. A lot of spill wipped upwith paper towels. I expected this stuff to get hot so I set the mixed container inside the other mixing container they provided and set it on the floor. As I was finishing cleaning up, I noticed the sides of both mixing cups bulging from the heat. I have an infared thermometer so I aimed it at the mixed surplus. It registered 233 degrees. I let the boards sit in the clamps for 7 days. I removed the clamps and cut out the oars. The joints look very good. I didn't know how to store the remaining unused surplus solution that had the pumps in it. So I just left the pumps in the bottles and set them back into the big zip loc bag. I wish they would include instructins for how to store the leftover - remove the pumps or leave them in the bottles?

Was this review helpful to you?

Verified Purchase

The product worked exactly as intended and the mix was perfect thanks to the pumps specifically designed to give you the perfect mix.

Was this review helpful to you?

Verified Purchase

I have used this item to repair the floor of a boat.

Was this review helpful to you?

Verified Purchase

I have never used epoxy before and I'm now deep into a boat floor repair. I don't have anything to compare to, but this product it's everything I needed.

Was this review helpful to you?