This item is eligible for free shipping

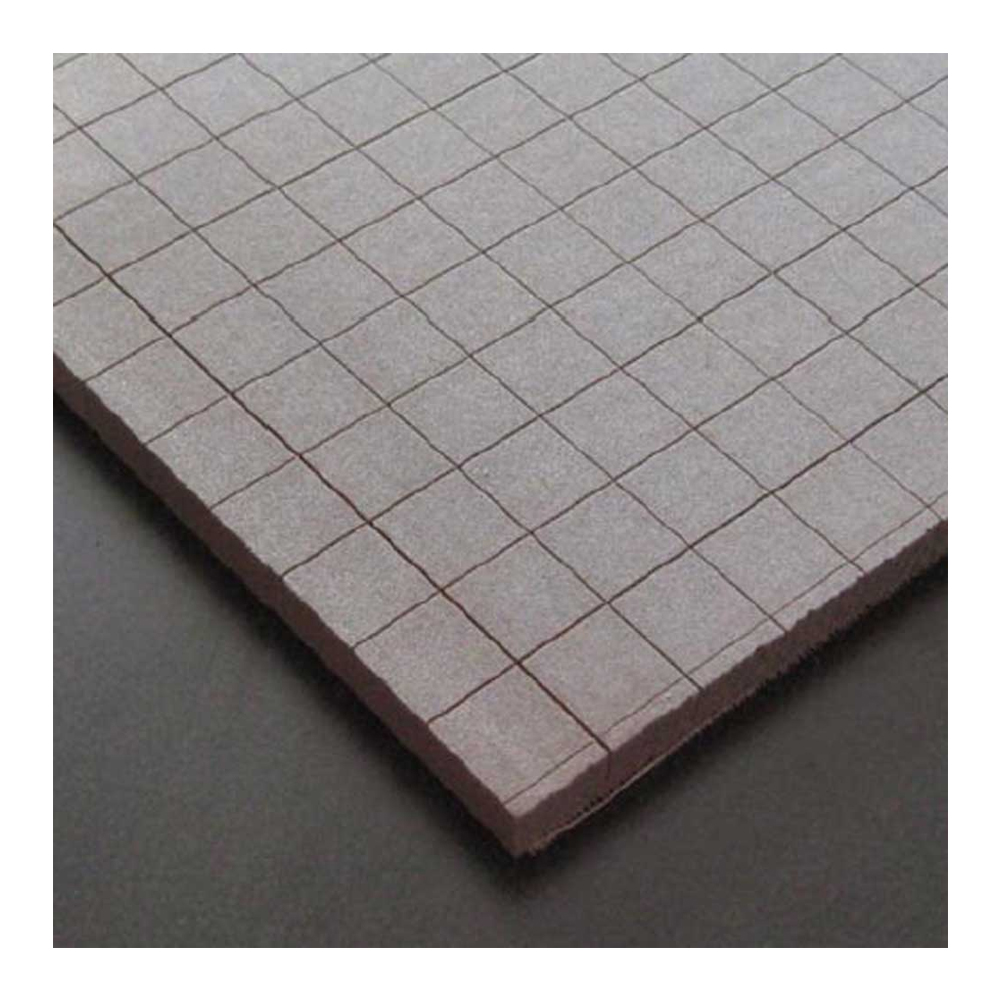

Carbon Fiber Twill Weave Cloth is a high strength, high modulus cloth. It has a high stiffness ratio, and a high strength-to-weight ratio as well. The Twill weave is characterized by the "twill line" or diagonal rib. Each tow warp end floats over two or more picks (depending on the twill formation.) Twills are very pliable and have excellent drape while maintaining stability.

Reviews for Carbon Fiber 2x2 Twill Weave

Verified Purchase

Worked out great for my custom air inlet for my 34 ford truck project

Was this review helpful to you?

Verified Purchase

I have made it a regular go to consumable in my projects, motorcycle brackets or inlays, Jet ski chine repair and skinning , letter openers for gifts, works well with the 2 to 1 epoxy.

Was this review helpful to you?

Verified Purchase

I use this product to make the hull, keel and rudder of a Marblehead RC sailboat.

Was this review helpful to you?

Verified Purchase

Purchased the carbon from JD because of the amazing reviews saying how pristine looking the carbon was. Dont get me wrong, great price and a great product, but considering I bought this for a show cause and not a structural, I am rather dissapointed. I spent hours removing imperfections about an inch long over the entire piece, and I didnt get it all out. Not was I was hoping for.

Was this review helpful to you?

As a beginner, it was as easy as it gets working with composite. Thanks a lot!

Was this review helpful to you?

I have tried numerous Carbon fiber suppliers from around the world including Japanese and Italian made Carbon fiber. By far Jamestown distributors carries the best Carbon fiber in terms of strength to weight ratio and price. This carbon fiber twill weave is excellent for infusion. The weave isn't to tight and isn't to loose. [@]

Was this review helpful to you?

I use thiss CF in speedboards, and it's really good. The fibers are nice, and the finished result is very good looking and stiff. I'm not very used to carbonfiber, so i messed ut the twill direction a little bit the first time. The cloth is easy to apply, and leaves a strong surface. I use the cloth in vacuumbags with foam molds.

Was this review helpful to you?

I have a large amount of experience in composite materials and I have to say this carbon fiber is the best material I have used. The carbon weave is tight and uniform throughout the entire piece. There were no scars or marks anywhere on the carbon fiber. The material was pristine and the packaging was great. I would recommend this product to anyone.

Was this review helpful to you?

I use this in race cars and on show cars. The weave retention is great, and is very consistant, having no permanent flaws. It molds well and isnt as brittle as the cheaper carbon from other sources. Overall, it is a really good product.

Was this review helpful to you?