Options

Quantity

1 yd contains 1 yd

This item is eligible for free shipping

Product Details

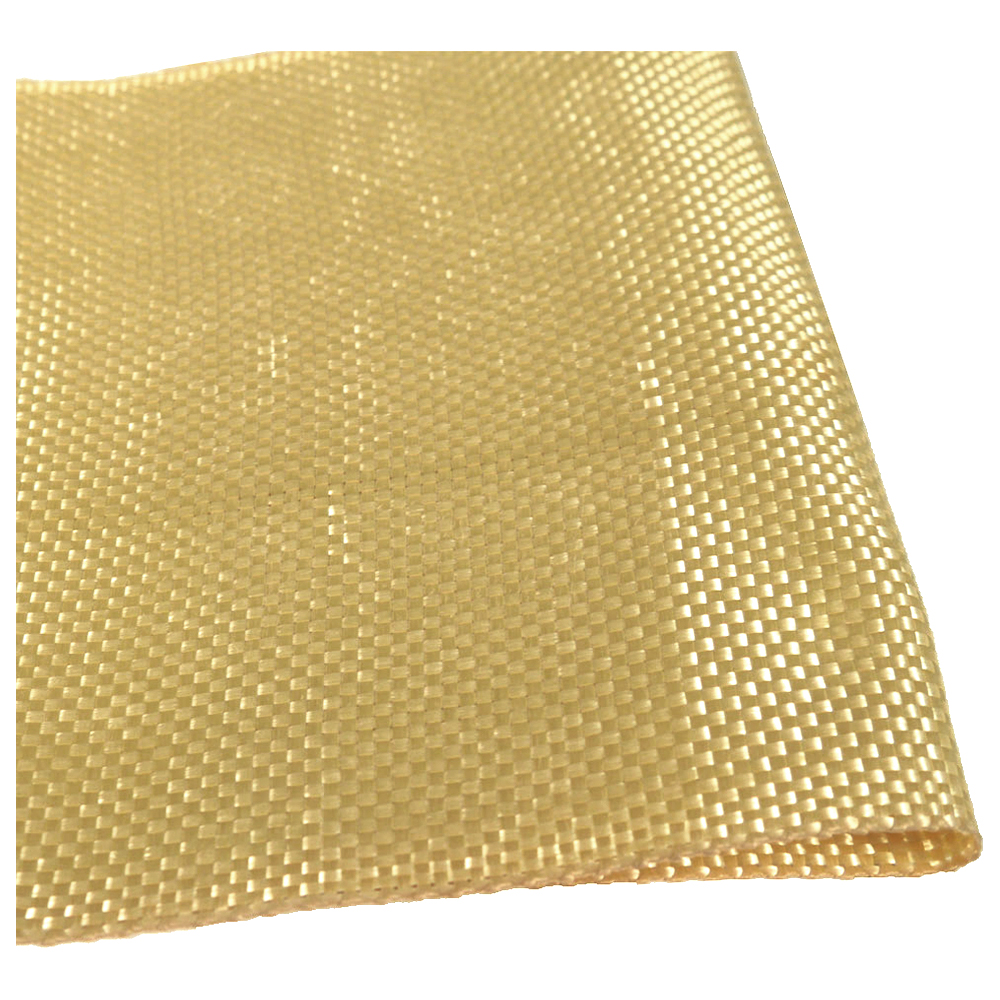

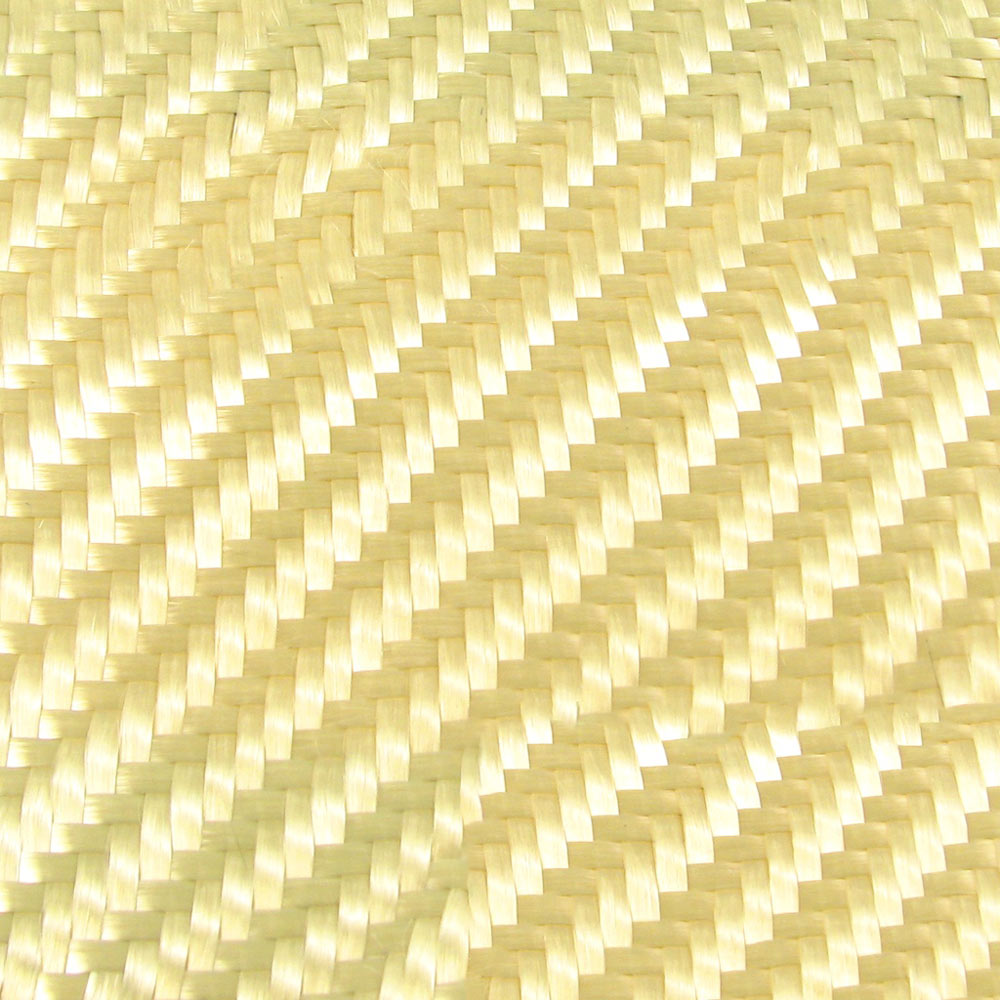

Plain weave 5 oz. Kevlar cloth is a high tensile strength and high modulus composite fabric, great for canoes, kayaks and racing shells where maximum strength and minimal weight are critical. Impact, tear and penetration resistance is far superior to fiberglass. 0.01 in thick 58 inches wide. Sold by the yard.

Info & Guides

Kevlar was developed in the early 1960's by Dupont. Assuming the same weight, Kevlar is literally five times stronger than steel. Kevlar fibers also have 43 percent less density than fiberglass. Originally developed to replace steel tire belts, it is an aramid with high strength and notable heat resistance. Kevlar's biggest weakness is its lack of compressive strength.Thermal properties

Highly flame resistant

Can handle temperatures to 320 degrees F for extended periods with ease

Significantly lighter than even E-glass

Will not melt (at 800 degress F it begins to decompose)

Why is Kevlar so useful for composites? A few reasons:

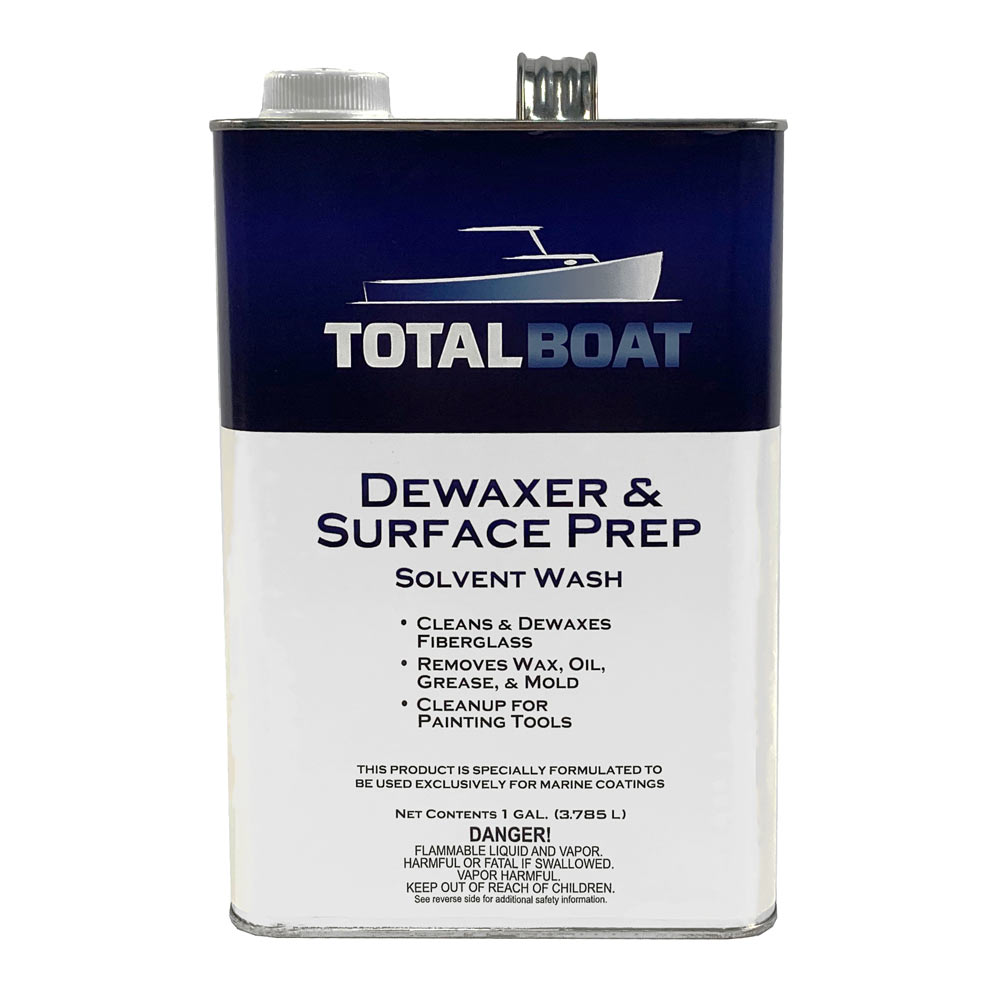

Recommended Products

Jamestown Distributors

Plastic Paint Pails

Starting at $3.75

rating out of 5 stars

EC Cutter

EC Cutter Electric Cordless Scissors

Starting at $139.70

rating out of 5 stars

WEST System

WEST System 105 Epoxy Resin

Starting at $49.97

rating out of 5 stars

WEST System

WEST System Epoxy Kit

Starting at $176.97

rating out of 5 stars

WEST System

WEST System 8002 Roller Cover

Starting at $8.77

rating out of 5 stars

Jamestown Distributors

Epoxy Spreaders - Single Edge

Starting at $3.92

rating out of 5 stars

Jamestown Distributors

Epoxy Spreaders - Single Edge

Starting at $3.92

rating out of 5 stars

Core-Cell

Double-Cut Core-Cell 5lb / cu. Ft Sheets

Starting at $114.62

rating out of 5 stars