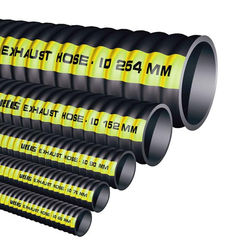

Shieldsflex II Marine Water and Exhaust Hose

This item is eligible for free shipping

This item will require additional time to ship

Shieldsflex II Series Marine Water and Exhaust Hose can be used on engine intakes, wet exhaust connections where bends or longer lengths are required, bilge pump intake and discharge, scupper lines, toilets, and holding tanks.

Shieldsflex II features a black synthetic rubber tube and cover. Wire is used to reinforce the hose between plies of synthetic cord. These hoses are resistant to odors, permeation, abrasion, exhaust fumes, ozone, mild chemicals, antifreeze, and saltwater.

Available in various lengths of 10', 12' and 50' depending on diameter size. Please click the "Product Info" tab for a detailed list. Please call for specific lengths and requests.

Reviews for Shieldsflex II Marine Water and Exhaust Hose

Verified Purchase

Very good replacement. More flexible pipe, easier to install. Good quality 10/10.

Was this review helpful to you?

Verified Purchase

Used on fresh water intake to sea strainer to pump worked great

Was this review helpful to you?

Decided to replace all the fresh water lined on my 1985 MasterCraft Stars & Stripes. This is a quality product; now I don't have to replace them for another 33 years.... :-). $22 shipping charge was a little on the high side, that why I only gave the transaction 4 stars

Was this review helpful to you?

Verified Purchase

Yes! This is exactly what we needed and Jamestown Distributors offered best price, delivered fast! Amazing, wonderful experience.. couldn't be happier with the product or the service.

Was this review helpful to you?

Verified Purchase

Great product. Just what I needed. Easy to cut to length and install.

Was this review helpful to you?

Verified Purchase

This marine exhaust hose is the best

Was this review helpful to you?

Verified Purchase

Use as engine cooling water intake and water distribution.

Was this review helpful to you?

Verified Purchase

I am repowering a 21' Scarab with 530 HP 496 stroker. This ShieldsFlex hose is the only hose I'll use for the raw water system. This hose is not cheap, but it won't kink or collapse and it'll accept a pretty tight radius for 1-1/4" wire core hose. Plus the blue strip compliments the translucent blue valve covers on the engine! I'm fastening the hose runs with Anchor SS Cushion clamps for a clean and robust installation. The fuel and oil lines are all stainless braid with AN fittings.

Was this review helpful to you?

Great heavy duty product that is flexible enough to easily replace the old one. Fast reasonable shipping.

Was this review helpful to you?

Verified Purchase

Raw Water pump

Was this review helpful to you?