This item is eligible for free shipping

TotalBoat Penetrating Epoxy is a low-viscosity wood rot restoration and repair solution that seals deeper & cures stronger than industry-leading penetrating epoxies. It has no VOCs, no odor & is 100% waterproof once cured.

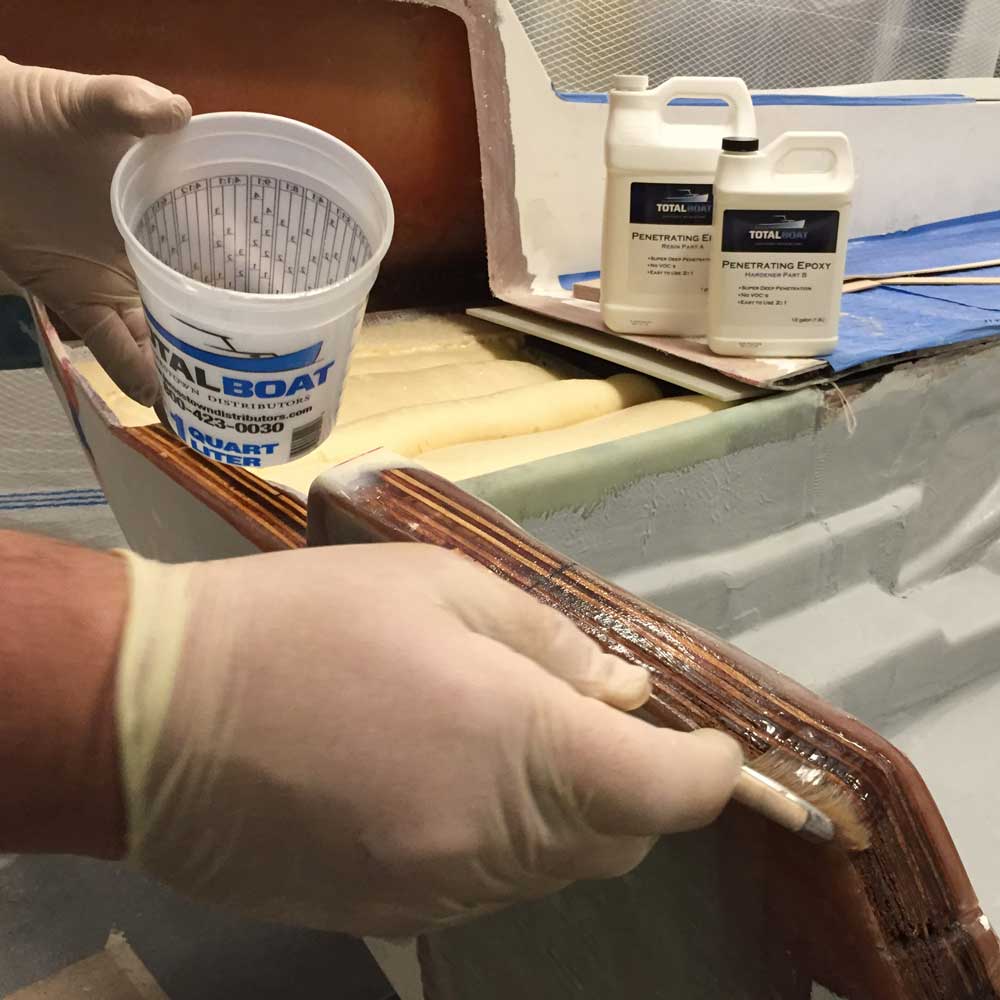

This 2:1 system is ideal for restoring rotten or damaged wood, or sealing new wood for lasting protection against humidity, salt, mold & mildew. It works by gluing cellulose (wood) fibers back together, sealing a bare, porous wood surface from the inside out. Double the penetrating power by mixing acetone with the epoxy resin solution in equal volume. Easy to apply by brush, roller, or inject via syringe. Surfaces may be painted or varnished after light sanding.

Choose from Traditional (65-90 F) or Cold Weather (40-65 F) formulas in Pint, Quart, 1/2 Gallon & Gallon kits.

| PENETRATING EPOXY HANDLING PROPERTIES | VALUE | TEST METHOD |

|---|---|---|

| Resin Density at 75°F, lbs/gal | 9.3 | ASTM D1475 |

| Hardener Density at 75°F, lbs/gal | 8.0 | ASTM D1475 |

| Resin Viscosity at 75°F, cP | 100 | ASTM D2196 |

| Hardener Viscosity at 75°F, cP | 20 | ASTM D2196 |

| Mix Ratio by Weight | 100A:44B | Calculated |

| Mix Ratio by Volume | 2A:1B | Calculated |

| Initial Mixed Viscosity at 75°F, cP | 50 | ASTM D2196 |

| Gel Time at 75°F, 150 gram mass, min | 45-50 | ASTM D2471 |

| Tack Free Time at 75°F, hrs | 36-48 | Calculated |

| Application Temperature Range | 65-90°F | -- |

| COLD WEATHER PENETRATING EPOXY HANDLING PROPERTIES | VALUE | TEST METHOD |

|---|---|---|

| Resin Density at 70°F, lbs/gal | 9.5 | ASTM D1475 |

| Hardener Density at 70°F, lbs/gal | 8.9 | ASTM D1475 |

| Resin Viscosity at 70°F, cP | 360 | ASTM D2196 |

| Hardener Viscosity at 70°F, cP | 270 | ASTM D2196 |

| Mix Ratio by Volume | 2A to 1B | Calculated |

| Mix Ratio by Weight | 100A to 47B | Calculated |

| Initial Mixed Viscosity at 70°F, cP | 300 | ASTM D2196 |

| Pot Life at 70"F, 150 gram mass, minutes | 10-15 | ASTM D2471 |

| Tack-Free Time at 70°F, hours | 4-6 | -- |

| Full Cure at 70°F, days | 2 | -- |

| Pot Life at 40°F, minutes | 40-50 | ASTM D2471 |

| Tack-Free Time at 40°F, hours | 16-24 | -- |

| Full Cure at 40°F, days | 4 | -- |

| Application Temperature Range | 40-65°F (do not use above 70°F) | -- |

Cleanup is easy. Wear latex gloves, wash off with soap and water. No solvents required.

APPLICATION NOTE: The wood must be bare and unfinished. Also, TotalBoat Penetrating Epoxy will not penetrate and level well when applied over some stains. Always test an area first. DO NOT USE on top of Minwax oil-based stains.

TotalBoat Cold Weather Penetrating Epoxy is perfect for use during the colder seasons. Compared to our traditional TotalBoat Penetrating Epoxy, our Cold Weather formula offers similar performance characteristics, but cures completely and reliably in cooler temperatures. Its tack-free properties also allow you to sand sooner.

WARNING: TotalBoat Cold Weather Penetrating Epoxy should not be used as a fast-cure epoxy in warmer temperature conditions because doing so can be unsafe and result in premature exotherm, brittleness, and improper curing.

Application Temperature Ranges:

- Traditional formula - 65-90°F

- Cold Weather formula - 40-65°F

Technical Information

Use For:

- Sealing open wood pores

- Glues wood fibers back together

- Fungi & mildew protection

- Rotten wood restoration

Traditional Formula and Cold Weather Formula Kit Volumes: Total Mix Ratio

- Pint Kit: total mix ratio 1.5 Pints (1 pint resin, 1/2 pint hardener)

- Quart Kit: total mix ratio 1.5 Quarts (1 quart resin, 1 pint hardener)

- Half-Gallon Kit: total mix ratio .75 Gallons (1 half gallon resin, 1 quart hardener)

- Gallon Kit: total mix ratio 1.5 Gallons (1 gallon resin, 1/2 gallon hardener)

Reviews for TotalBoat Penetrating Epoxy Kits

Verified Purchase

Very easy to mix up a batch and apply to Red Cedar lumber. I'm applying it to the lumber I will be building a deck with. So far all the projects I've built for outside I have applied this epoxy too and they keep the same look through out the year. No fading, nothing.

Was this review helpful to you?

Verified Purchase

I used this epoxy to protect the plywood for my boat deck that I build. Epoxy took a little longer than expected to settle but that's because it was cold and dark but after all it got really hard as it's supposed to be !

Was this review helpful to you?

Verified Purchase

Made a patio table from 6/4 red oak for a family member and wanted it to be able to stay outdoors year round. A friend told me about TOTAL BOAT penetrating epoxy. After discussing the application with total boat tech support, they were extremely helpful guiding me on proper wood prep application, preparing between coats and the need to apply a spar varnish (Goeam 2.0) for best UV protection. I applied 2 coats of penetrating epoxy and 3 coats of varnish. The table is finished but, still in my shop awaiting delivery to RI. I am extremely please with the results so far and can't wait to see how it performs in its final home. Total bolt folks are the best and extremely easy to work with and go the extra mile to provide a first time user with all the tricks and details to get the job done right. I will be a routine customer and will recommend total boat to my friends and fellow woodworkers.

Was this review helpful to you?

Verified Purchase

I used it for repairing a 70+ year old gun stock and it worked perfectly.

Was this review helpful to you?

Verified Purchase

It is great stuff for sealing unfinished wood, I have used it before ad will use it again. It soaks into rotted fibers and stops the rot.

Was this review helpful to you?

Verified Purchase

So far this product has worked as it should. Looks great and only operator errors have caused, the very few, mishaps. Camper is almost done.

Was this review helpful to you?

Verified Purchase

Worked as advertised and shipping speed was very fast. 100% satisfied. Great company too

Was this review helpful to you?

Verified Purchase

Worked as advertised and shipping speed was very fast. 100% satisfied. Great company too

Was this review helpful to you?

Verified Purchase

Worked as expected. Great penetration with thinning

Was this review helpful to you?

Verified Purchase

First attempt at epoxy resin inlays using these two products. Sealed the wood using the penetrating epoxy to stop color bleed. MakerPoxy used to create fill images on 12"x9" charcuterie boards.

Was this review helpful to you?