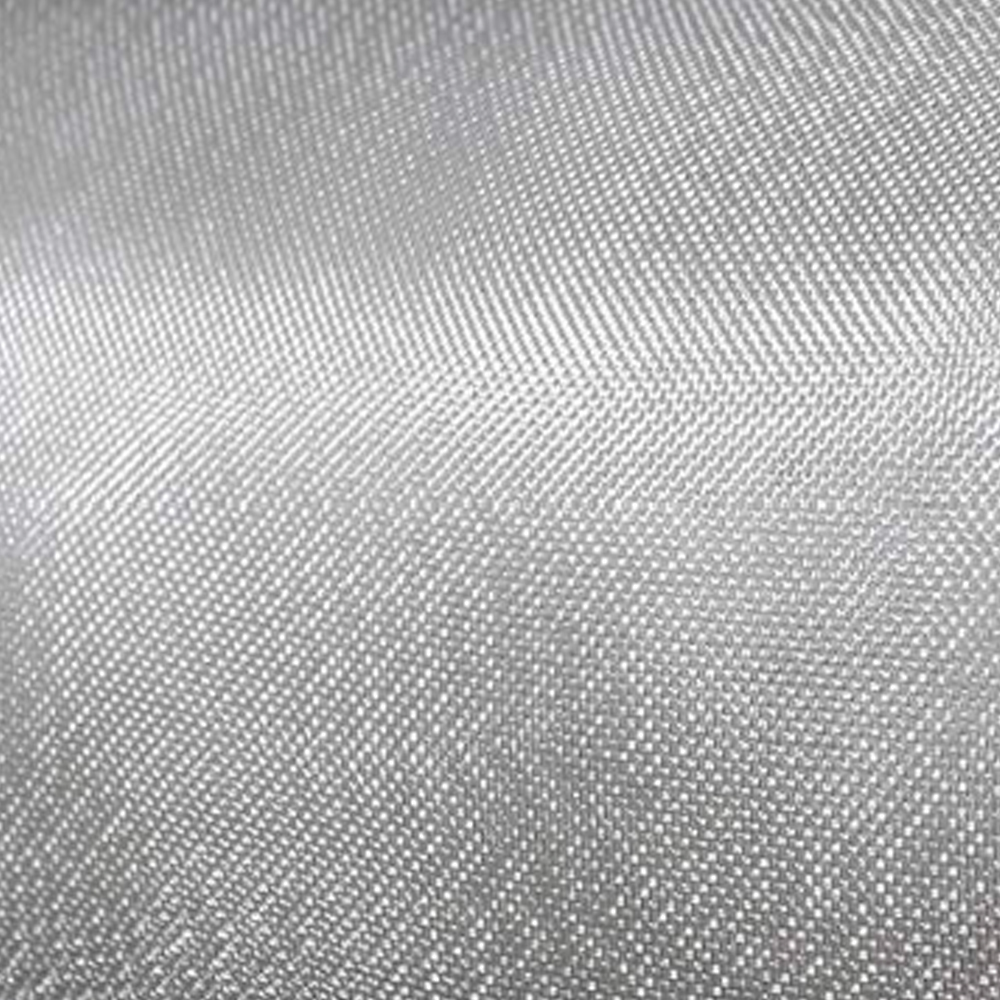

Fiberglass cloth is a woven material available in various sizes to allow custom strength, thickness, and weight in projects. Fiberglass cloth provides great strength and durability when layered with a resin to form a hardened composite.

Fiberglass cloth has many advantages: Fiberglass cloth has greater tensile strength than steel wire of the same diameter. Excellent fire and heat resistance. Thermal conductivity (making it useful for insulation applications) and chemical resistance properties similar to glass. Durable and economical.

Reviews for Fiberglass Cloth - 4 Ounce

Verified Purchase

It should have been rolled on a tube

Was this review helpful to you?

Verified Purchase

I'm doing extensive repair.ro the Flybridge on my Grand Banks. I am trying to make it "as built" as much as possible and this material is very close to what was used in the original construction. It was easy to work with and made a beautiful job. I'm glad I bought the extra package as I'm sure it will get used somewhere on the boat.

Was this review helpful to you?

Verified Purchase

When ordering 12 yds of material for a cedar strip build, it would be preferable to receive it in one continuous roll instead of in four separate 3yd folded sections.

Was this review helpful to you?

Verified Purchase

I used it to strengthen seams in ply flooring in my boat. I should have purchased a role in a narrow strip 6 to 10 inches. I had trouble cutting equal size strips because the fabric was not consistent throughout.

Was this review helpful to you?

Verified Purchase

Not much more to say, product was exactly what it said it was and worked perfectly for my use.

Was this review helpful to you?

Verified Purchase

I ordered the 4 oz fabric and the slow cure resin. If you need extra time to paddle out your epoxy resin, I would definitely recommend the slow cure hardener! I found that I needed the full half hour (really, more like 20 minutes before things start to get jello-like) to evenly distribute my fiberglass resin for my aft deck kayak glassing. Sands really nicely too!

Was this review helpful to you?

Verified Purchase

Boat bottom protection

Was this review helpful to you?

Verified Purchase

Used this for a canoe

Was this review helpful to you?

Verified Purchase

I bought this cloth for a stitch and glue kayak project. I have used some of the cloth in the bottom inside and it went in smoothly. I am still preparing the bottom outside for glass.

Was this review helpful to you?

Verified Purchase

I used the 4 oz. fiberglass cloth and Total Boat Epoxy Resin & Hardener to fiberglass a canoe paddle I made. The fiberglass cloth wet out beautifully and wrapped around the edges of the paddle with no problem.

Was this review helpful to you?